Need Support?

Please provide your question. We’ll find you with the best support options.

Table of Contents

1. Industry Application Examples

2. Miniature Bearing Size Chart and Catalogues Download

3. Enterprise Scale and Certifications

5. Solution for Wobbling Rear Guide Wheel on Bicycle: Case Study of Miniature Ball Bearings

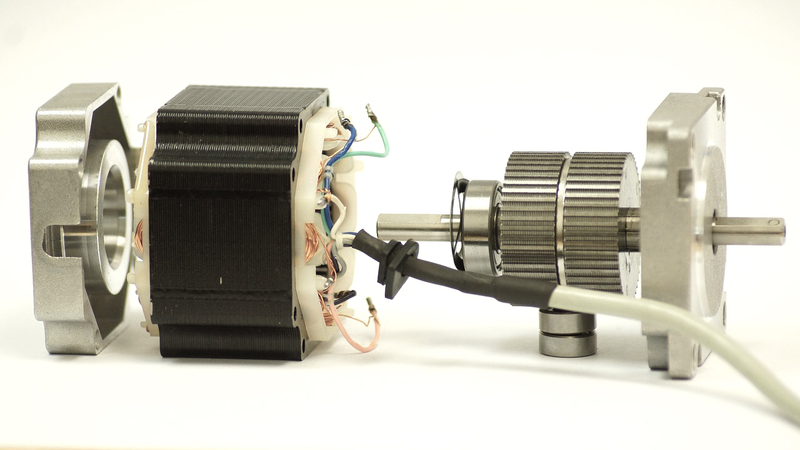

Motor bearings are essential components in the world of machinery, responsible for enabling smooth rotational motion while reducing friction. Found in a wide range of applications, from automotive engines to industrial equipment, motor bearings are vital for maintaining the efficiency and reliability of these systems.

Modern consumers are increasingly demanding whether home appliances are comfortable, safe, energy-saving, and environmentally friendly or not. Using durable, high-precision, low-vibration, high-quality bearings not only can reduce the energy consumption of mechanical operation but also save you more energy and cost on maintenance and replacement parts in the future to be more energy-saving and environmental protection.

Miniature Bearings are critical in precision instruments and experimental equipment. For example, they are applied in optical instruments, laser devices, medical equipment, measurement instruments, etc., to achieve precise motion control and positioning requirements.

If you're using bearings in other industries, let us know your application requirements — we'll recommend the most suitable bearings for you.

| Bearing No. | Bore(d) (mm) | Outer(D) (mm) | Width(B) (mm) | Weight (g) | D1 | C1 | C2 |

|---|---|---|---|---|---|---|---|

| 604 | 4 | 12 | 4 | 2.19 | 13.5 | 1 | 1 |

| 624 | 4 | 13 | 5 | 3.1 | 15 | 1 | 1 |

| 634 | 4 | 16 | 5 | 5.24 | 18 | 1 | 1 |

| 674 | 4 | 7 | 2 | 0.23 | 8.2 | 0.6 | 0.6 |

| 684 | 4 | 9 | 2.3 | 0.65 | 10.3 | 0.6 | 0.6 |

| 694 | 4 | 11 | 4 | 1.69 | 12.5 | 1 | 1 |

| 605 | 5 | 14 | 5 | 3.46 | 16 | 1 | 1 |

| 625 | 5 | 16 | 5 | 4.95 | 18 | 1 | 1 |

| 635 | 5 | 19 | 6 | 8.5 | 22 | 1.5 | 1.5 |

| 675 | 5 | 8 | 2 | 0.25 | 9.2 | 0.6 | 0.6 |

| 685 | 5 | 11 | 3 | 1.16 | 12.5 | 0.8 | 1 |

| 695 | 5 | 13 | 4 | 2.39 | 15 | 1 | 1 |

| 606 | 6 | 17 | 6 | 5.94 | 19 | 1.2 | 1.2 |

| 626 | 6 | 19 | 6 | 8.12 | 22 | 1.5 | 1.5 |

| 636 | 6 | 22 | 7 | 13.9 | |||

| 676 | 6 | 10 | 2.5 | 0.55 | 11.2 | 0.6 | 0.6 |

| 686 | 6 | 13 | 3.5 | 1.87 | 15 | 1 | 1.1 |

| 696 | 6 | 15 | 5 | 3.85 | 17 | 1.2 | 1.2 |

| 607 | 7 | 19 | 6 | 7.8 | |||

| 627 | 7 | 22 | 7 | 12.7 | 25 | 1.5 | 1.5 |

| 637 | 7 | 26 | 9 | 24.2 | |||

| 677 | 7 | 11 | 2.5 | 0.59 | 12.2 | 0.6 | 0.6 |

| 687 | 7 | 14 | 3.5 | 2.03 | 16 | 1 | 1.1 |

| 697 | 7 | 17 | 5 | 5.26 | |||

| 608 | 8 | 22 | 7 | 11.8 | 25 | 1.5 | 1.5 |

| 628 | 8 | 24 | 8 | 17.1 | |||

| 638 | 8 | 28 | 9 | 28.1 | |||

| 678 | 8 | 12 | 2.5 | 0.7 | 13.2 | 0.6 | |

| 688 | 8 | 16 | 4 | 3.11 | 18 | 1 | |

| 698 | 8 | 19 | 6 | 7.12 | 22 | 1.5 | 1.5 |

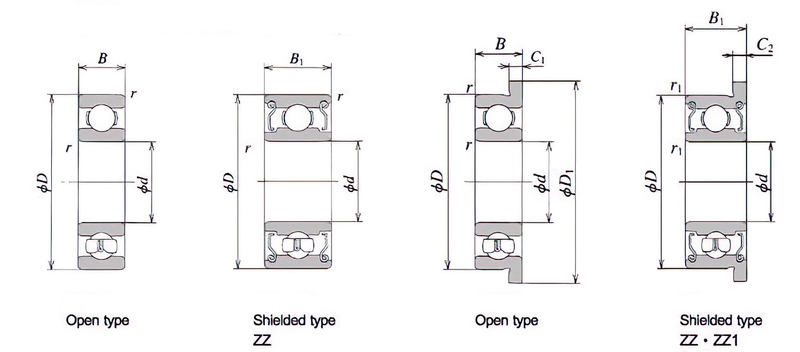

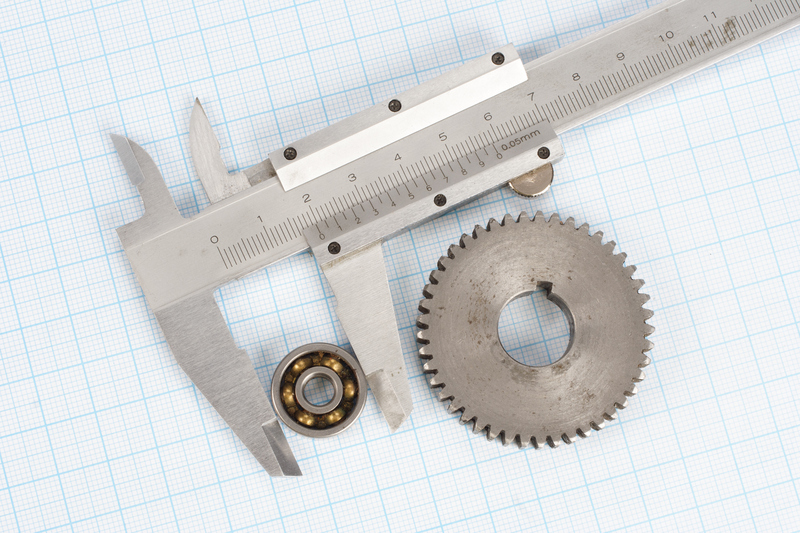

This size chart provides a partial list of miniature bearing dimensions, including outer diameter (OD), inner diameter (ID), and width (W). Understanding these dimensions is crucial for finding the perfect fit in your application, ensuring optimal performance and space-saving integration.

Miniature Bearings Catalogues Download

Miniature Bearings Catalogues Download

With IATF 16949, RoHS, and REACH certifications, we adhere to international standards, ensuring that our products not only meet the highest quality standards but are also environmentally friendly.

High-quality miniature ball bearing supplier for industrial applications.

Key Features of Miniature Ball Bearings

Bore(d)<10mm

High Speed

Light Weight

Miniature bearings are characterized by their compact size, lightweight construction, high speed capability, and high precision. They are typically made of metal, and consist of rolling elements (usually steel balls or cylindrical rollers) along with outer and inner rings.

The dimensions of miniature bearings are typically expressed in metric units, such as inner diameter, outer diameter, and width. Common sizes include 3mm, 4mm, 5mm, and so on.

A bicycle brand reported that the rear guide wheel showed noticeable wobbling after prolonged use, causing unstable chain operation and affecting overall riding performance and experience.

A thorough investigation revealed that the issue primarily stemmed from the miniature ball bearing(model: 607-2RS) provided by the original supplier, where the gap configuration had not been optimized according to actual requirements.

Through in-depth customer consultations and problem analysis, we identified that the oil leakage issue originated from a design flaw in the cover structure provided by the original supplier. To address this, we developed a customized solution, which included:

We provide high precision miniature ball bearings in large quantities and accept customized orders.

Please provide your question. We’ll find you with the best support options.