Need Support?

Please provide your question. We’ll find you with the best support options.

Table of Contents

2. Production Capacity Showcase

3. Showcasing ISK’s Recent Customer Applications

4. Industry Application Examples

5. Enterprise Scale and Certifications

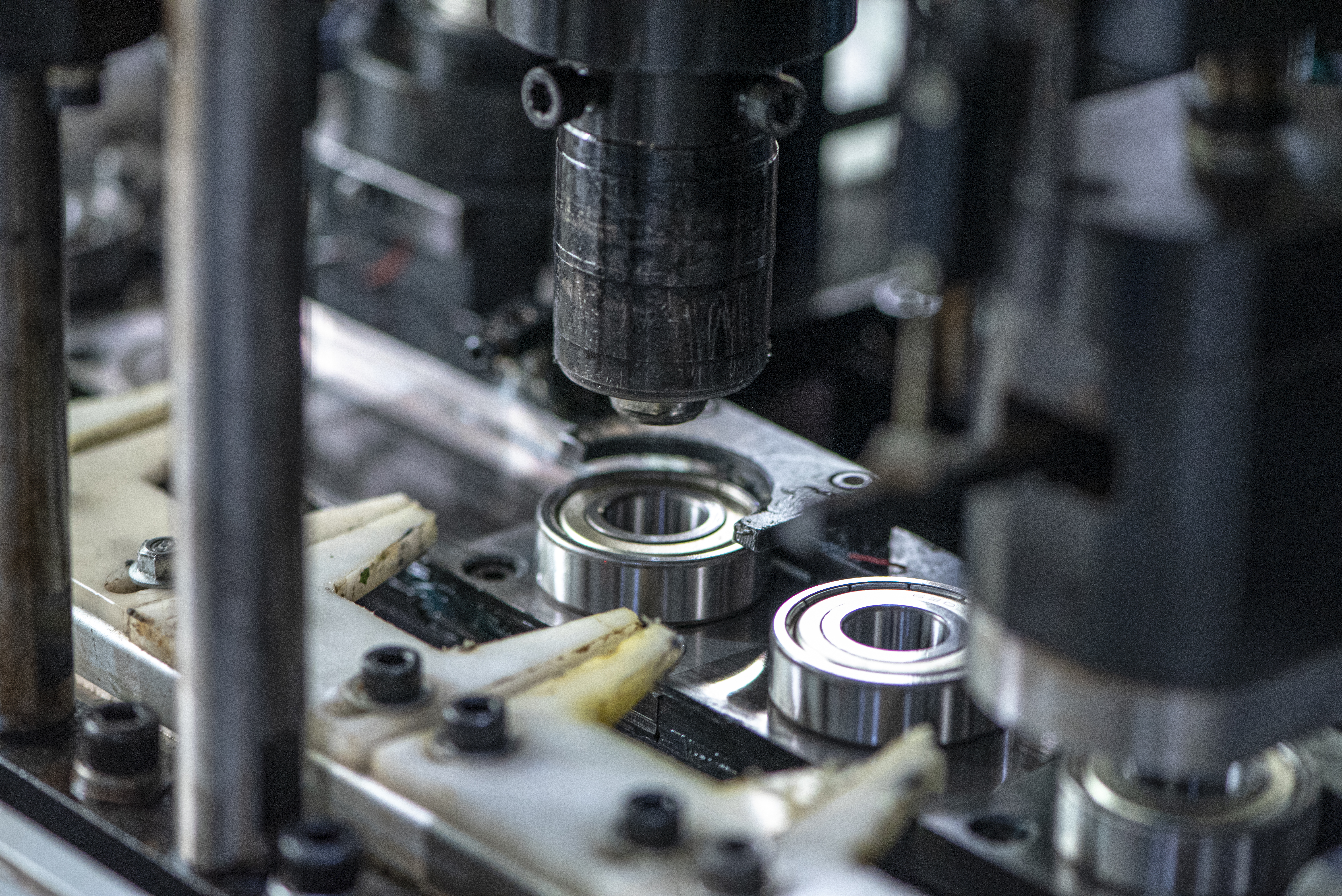

A 100% Automated Production Process

One distinctive advantage we possess is the utilization of a 100% automated production process. This technology enables us to ensure consistent quality at every stage of manufacturing.

We understand that each customer's needs are unique, so we tailor solutions to closely align with individual requirements. Whether it's standard specifications or specially designed bearings for mass production, our team is capable of providing solutions seamlessly matched to your industry demands. Our commitment to flexibility and adaptability makes us a reliable partner for various manufacturing needs.

Our consulting team, well-versed in industry trends and standards, collaborates closely with customers to deliver the most suitable bearing solutions. This customized approach ensures that our customers receive not just satisfaction but products and services that surpass expectations.

To help keep things efficient and cost-effective for our partners, ISK sets a basic order threshold that fits large-scale production.

Production Line: 40, Factory Employee: 210

Office employee : 40, R&D: 2~3

A bicycle brand reported that the rear guide wheel showed noticeable wobbling after prolonged use, causing unstable chain operation and affecting overall riding performance and experience.

A well-known motor manufacturer in Asia frequently experienced abnormal bearing noise and irregular operation during equipment usage. Despite multiple inspections, the root cause could not be identified, resulting in a shortened product lifespan, decreased equipment stability, and significantly increased maintenance costs.

Motorcycle bearings play a crucial role in ensuring the smooth and efficient operation of various components within a motorcycle. From the wheels to the engine, bearings are integral to reducing friction and allowing parts to move freely.

Modern consumers are increasingly demanding whether home appliances are comfortable, safe, energy-saving, and environmentally friendly or not. Using durable, high-precision, low-vibration, high-quality bearings not only can reduce the energy consumption of mechanical operation but also save you more energy and cost on maintenance and replacement parts in the future to be more energy-saving and environmental protection.

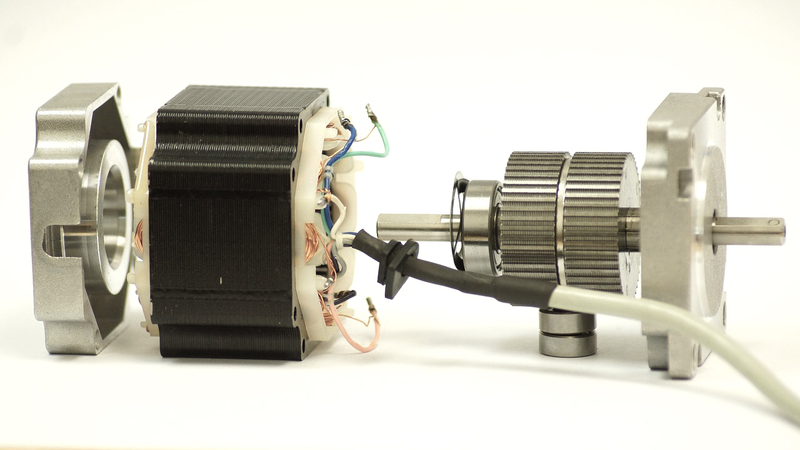

Motor bearings are essential components in the world of machinery, responsible for enabling smooth rotational motion while reducing friction. Found in a wide range of applications, from automotive engines to industrial equipment, motor bearings are vital for maintaining the efficiency and reliability of these systems.

Our bicycle bearings comply with the IATF 16949 automotive industry safety standards. We use 100% automated testing professional equipment to accurately control the noise value of each bearing. The outer cover seal design can avoid foreign object intrusion, avoid unnecessary noise and avoid unnecessary shaking. Therefore, it can provide users with a more comfortable and stable riding experience.

If you're using bearings in other industries, let us know your application requirements — we'll recommend the most suitable bearings for you.

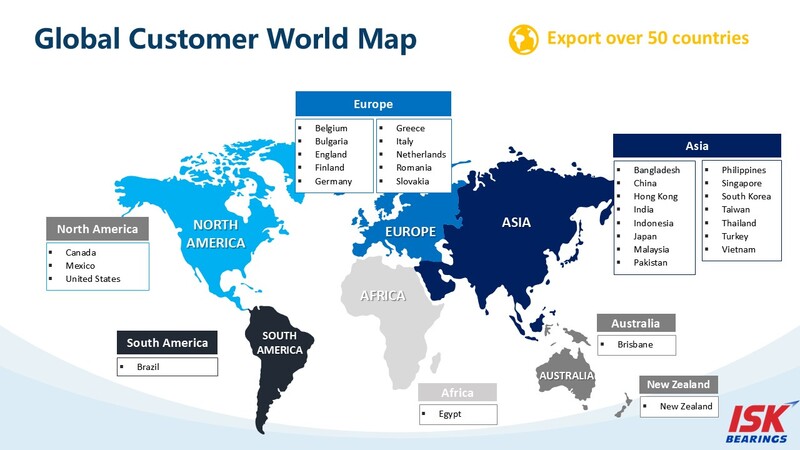

With IATF 16949, RoHS, and REACH certifications, we adhere to international standards, ensuring that our products not only meet the highest quality standards but are also environmentally friendly. With a monthly production capacity of 5 million units, our bearings are exported to over 50 countries, establishing our position in the global industry. Currently, we operate 40 production lines with ongoing expansion efforts, coupled with a professional R&D team, further solidifying our leading position in technological innovation.

At the core of our technological edge is our specialized expertise, characterized by an independent heat treatment facility and precision quenching capabilities. Many outsourced bearing factories, in an effort to save time and costs, often heat different thicknesses of steel together. This practice results in uneven heating of the steel, compromising durability. However, with our own heat treatment facility, we can precisely control each batch of bearings with varying thicknesses. This ensures that they achieve optimal hardness and toughness, significantly enhancing their durability.

ISK BEARINGS has achieved a perfect balance between high performance and cost-effectiveness. Our commitment to efficiency extends to the manufacturing process, allowing us to provide competitively priced ball bearings without compromising quality. Partners benefit from this cost-effective solution, enhancing their overall competitiveness.

In an era where technology continually drives industrial progress, ISK BEARINGS stands at the forefront, offering a range of bearings that combine innovation, precision, and reliability. Our technological edge encompasses automated testing, customer-centric solutions, scale of operation, and professional expertise, positioning us as a trusted partner across global industries. As we consistently push the limits of what is possible, our commitment to excellence remains steadfast, ensuring that our bearings are not just components but indispensable elements for advancing machinery.

*Given our large-scale capacity and commitment to manufacturing efficiency, certain minimum order quantities are required to maintain optimal resource allocation.

In the world of industrial machinery, precision is the key to efficiency, and ball bearings play a crucial role in ensuring seamless operation. In this article, we will delve into the cutting-edge technology and unique advantages that make ISK BEARINGS the preferred choice of manufacturers for ball bearings.

In the fast-paced and demanding field of industrial manufacturing, maintaining a leading position requires not only innovation but also a commitment to technological excellence. At ISK BEARINGS, we take pride in our technological edge, making us a leading supplier of bearings. Our steadfast commitment to quality, precision, and customer satisfaction is reflected in our advanced facilities and cutting-edge technology.

Please provide your question. We’ll find you with the best support options.