Need Support?

Please provide your question. We’ll find you with the best support options.

Poor quality bearings can cause noise. To strictly monitor each bearing, noise detectors are used to ensure the quality of each bearing and classify them as regular or motor grade to meet the needs of various customers.

The salt spray test is a machine for testing the bearings’ corrosion resistance by exposing them to a salt spray environment to evaluate whether the bearing meets the customer's requirements.

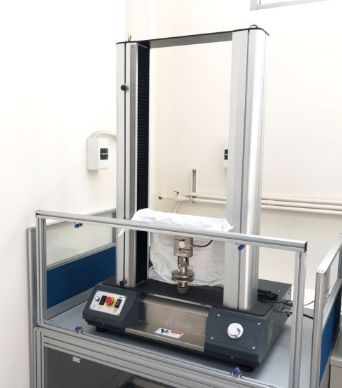

The main tests include crushing load, carrying capacity, crushing hardness, compressive strength, and load capacity of the bearings, and actual parameters are generated to assist customers in preliminary development.

The clearance of bearings directly relates to the noise, vibration, temperature, lifespan, and performance of the bearings assembled on the products. This shows clearance of bearings is critical. Therefore, we can ensure the performance of the bearing by adjusting the clearance.

The plug gauge is an essential inspection tool for checking the bearing hole size within the acceptable tolerance range.

The automatic appearance inspection machine’s function is to inspect the bearings whether the presence of dust, cracks, or breakage.

The dimensional inspection function is to check whether the dimensions of a bearing meet the specified specifications and tolerances.

Please provide your question. We’ll find you with the best support options.