Need Support?

Please provide your question. We’ll find you with the best support options.

Table of Contents

1. Industry Application Examples

2. 6000 Series Ball Bearing Catalogues Download

3. 6200 Series Ball Bearing Catalogues Download

4. 6300 Series Ball Bearing Catalogues Download

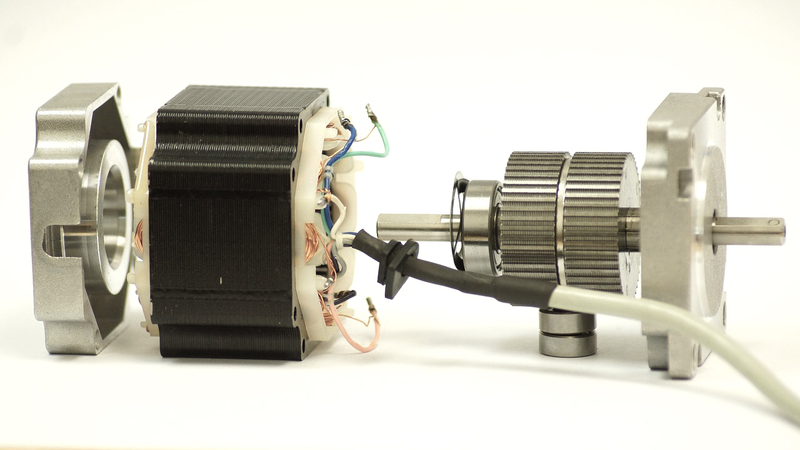

Motor bearings are essential components in the world of machinery, responsible for enabling smooth rotational motion while reducing friction. Found in a wide range of applications, from automotive engines to industrial equipment, motor bearings are vital for maintaining the efficiency and reliability of these systems.

Modern consumers are increasingly demanding whether home appliances are comfortable, safe, energy-saving, and environmentally friendly or not. Using durable, high-precision, low-vibration, high-quality bearings not only can reduce the energy consumption of mechanical operation but also save you more energy and cost on maintenance and replacement parts in the future to be more energy-saving and environmental protection.

deep groove ball bearings are commonly used in wheel hubs, transmission systems, and electric power steering units to ensure smooth and reliable vehicle performance.

If you're using bearings in other industries, let us know your application requirements — we'll recommend the most suitable bearings for you.

| Bearing No. | Bore(d) (mm) | Outer(D) (mm) | Width(B) (mm) | r (mm) | Dynamic (kgf) | Static (kgf) | Weight (g) |

|---|---|---|---|---|---|---|---|

| 6000 | 10 | 26 | 8 | 0.5 | 360 | 196 | 19 |

| 6001 | 12 | 28 | 8 | 0.5 | 400 | 229 | 22 |

| 6002 | 15 | 32 | 9 | 0.5 | 440 | 263 | 30 |

| 6003 | 17 | 35 | 10 | 0.5 | 470 | 296 | 39 |

| 6004 | 20 | 42 | 12 | 1 | 735 | 465 | 69 |

| 6005 | 25 | 47 | 12 | 1 | 790 | 525 | 80 |

This size chart provides a partial list of deep groove ball bearing dimensions, including outer diameter (OD), inner diameter (ID), and width (W).

Deep Groove Ball Bearings Catalogues Download

Deep Groove Ball Bearings Catalogues Download

| Bearing No. | Bore(d) (mm) | Outer(D) (mm) | Width(B) (mm) | r (mm) | Dynamic (kgf) | Static (kgf) | Weight (g) |

|---|---|---|---|---|---|---|---|

| 6200 | 10 | 30 | 9 | 1 | 400 | 229 | 32 |

| 6201 | 12 | 32 | 10 | 1 | 535 | 305 | 37 |

| 6202 | 15 | 35 | 11 | 1 | 600 | 360 | 45 |

| 6203 | 17 | 40 | 12 | 1 | 750 | 460 | 65 |

| 6204 | 20 | 47 | 14 | 1.5 | 1000 | 635 | 106 |

| 6205 | 25 | 52 | 15 | 1.5 | 1100 | 730 | 128 |

This size chart provides a partial list of deep groove ball bearing dimensions, including outer diameter (OD), inner diameter (ID), and width (W).

Deep Groove Ball Bearings Catalogues Download

Deep Groove Ball Bearings Catalogues Download

| Bearing No. | Bore(d) (mm) | Outer(D) (mm) | Width(B) (mm) | r (mm) | Dynamic (kgf) | Static (kgf) | Weight (g) |

|---|---|---|---|---|---|---|---|

| 6300 | 10 | 35 | 11 | 1 | 635 | 365 | 53 |

| 6301 | 12 | 37 | 12 | 1.5 | 760 | 450 | 60 |

| 6302 | 15 | 42 | 13 | 1.5 | 895 | 545 | 82 |

| 6303 | 17 | 47 | 14 | 1.5 | 1070 | 660 | 115 |

| 6304 | 20 | 52 | 15 | 2 | 1250 | 785 | 144 |

| 6305 | 25 | 62 | 17 | 2 | 1610 | 1080 | 232 |

This size chart provides a partial list of deep groove ball bearing dimensions, including outer diameter (OD), inner diameter (ID), and width (W).

Deep Groove Ball Bearings Catalogues Download

Deep Groove Ball Bearings Catalogues Download

With IATF 16949, RoHS, and REACH certifications, we adhere to international standards, ensuring that our products offer good quality, stability, and environmental friendliness.

High-quality deep groove ball bearing supplier for industrial applications.

Key Features of Deep Groove Ball Bearings

Widely Used

Simple Construction

Combined Load

.webp)

Deep groove ball bearings are one of the most common and widely used types of bearings in industrial, mechanical, and automation applications. They are employed to support rotating shafts, wheels, or other components requiring rotation, reducing friction and facilitating smoother operation of mechanical systems.

Deep groove ball bearing generally consists of an inner ring, an outer ring, a spherical rolling element and a cage.The orbital ditch is slightly larger than the radius of the steel ball.Due to the point contact between the ball and the track, the deep groove ball bearing can withstand the bidirectional axial load in addition to the radial load.

Stainless steel bearings are a great choice when other materials might struggle, especially in harsh conditions. They offer better resistance to chemicals and corrosion, as well as improved stability in high-temperature environments. Just like standard deep groove ball bearings made from carbon chromium steel, stainless steel bearings feature deep raceway grooves and a close fit between the raceways and balls, ensuring smooth performance.

%206810%E4%B8%BB.png)

Chrome steel is the most common material used to produce the load carrying components in precision ball bearings, and it offers a cost-effective alternative to stainless steel. While less resistant to corrosion, chrome steel is durable and still resistant to corrosive factors in certain environments.

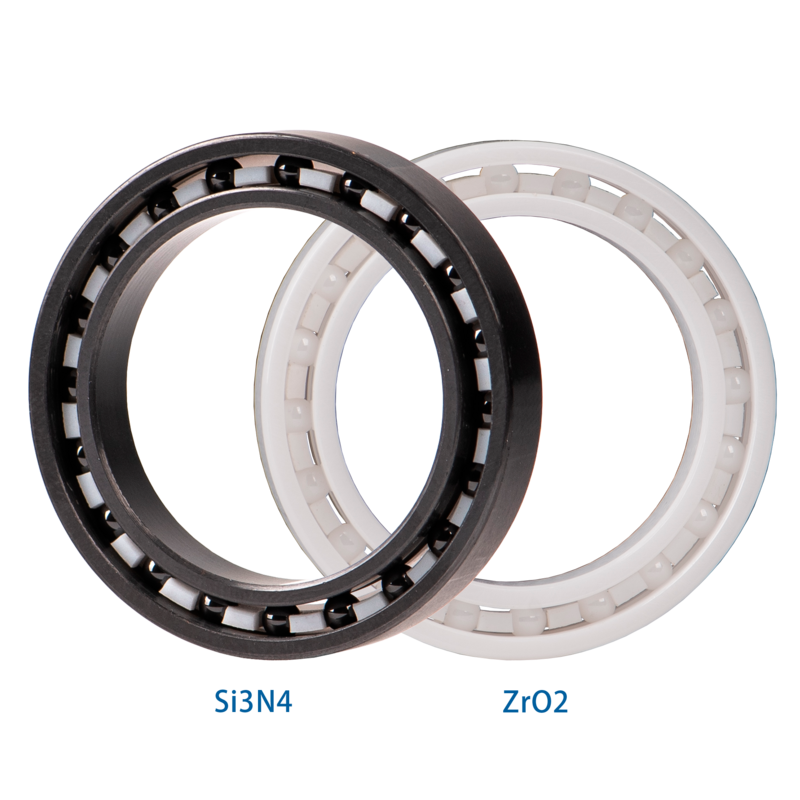

Ceramic ball bearings are made entirely from ceramic materials, such as Silicon Nitride (Si3N4) or Zirconium Oxide (ZrO2). Unlike steel bearings, they offer higher hardness and better elasticity. One of their standout features is that they can run without lubrication, making them ideal for environments where other bearings might fail. Ceramic bearings are highly resistant to corrosion, even in harsh conditions like concentrated acids or seawater. Additionally, they handle temperature fluctuations better, and their lifespan is significantly longer than that of steel bearings.

.jpg)

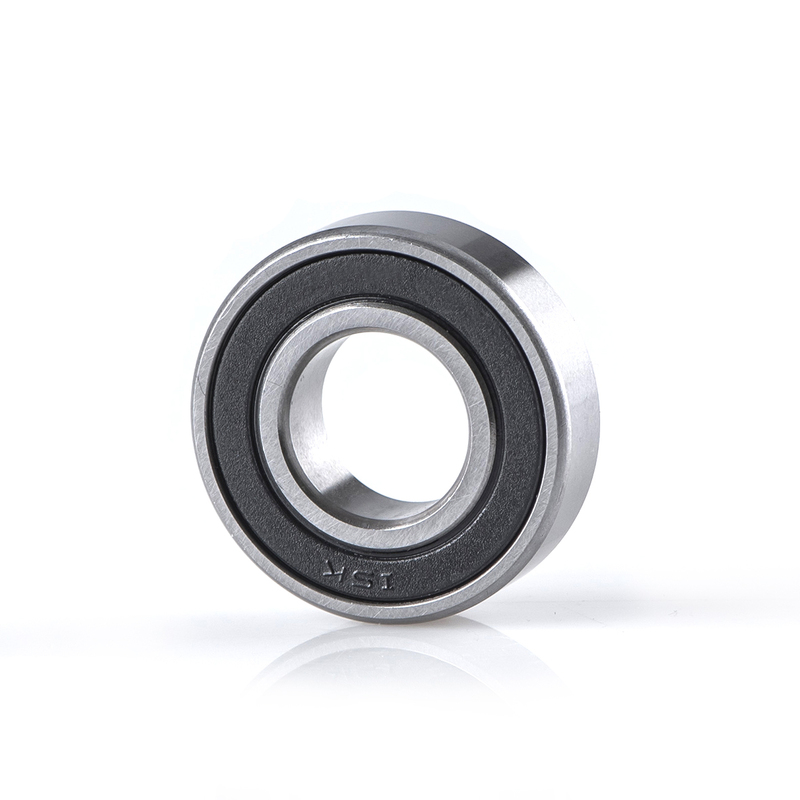

Sealed bearings feature an internal closure structure that effectively prevents external contaminants from entering the bearing. This design helps extend the bearing's lifespan, reduce maintenance requirements, and enhance operational efficiency. The sealing structure is typically made of rubber, effectively blocking dust, moisture, and other elements that could potentially damage the bearing.

Sealed bearings are particularly suitable for environments with harsh conditions, such as dusty, humid, or high-temperature surroundings. The sealing structure provides higher protective performance, ensuring stable operation even in challenging conditions.

1688%E4%B8%BB.jpg)

Shielded bearings, also known as metal-shielded bearings, have a relatively simpler structure, usually with metal shields covering the outer ring of the bearing. This design is more straightforward compared to sealed bearings, making it more economically practical in some applications.

Shielded bearings are suitable for relatively clean environments where there is less intrusion of dust or moisture. They are commonly found in lightweight mechanical applications where reduced weight and friction are crucial.

We provide high precision deep groove ball bearings in large quantities and accept customized orders.

Please provide your question. We’ll find you with the best support options.