Need Support?

Please provide your question. We’ll find you with the best support options.

ISK Bearings | B2B Bearing Wholesale

Table of content

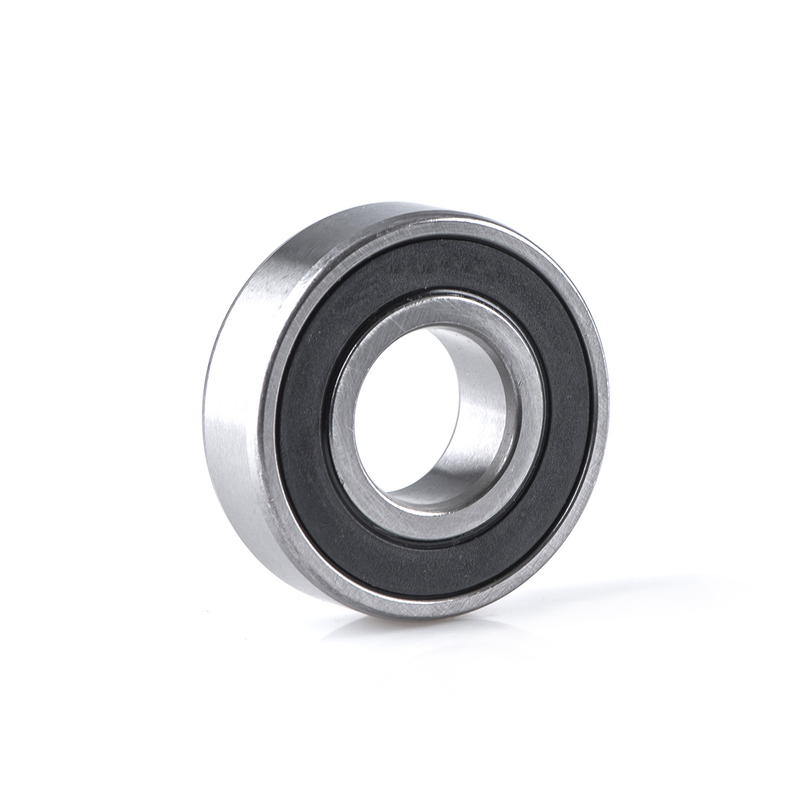

The 6200deep groove ball bearing is a common bearing model that is widely used in various machinery and equipment. In this article, we will delve into the dimensions of the 6200 bearing.

Deep Groove Ball Bearing 6200 Detailed Dimension Information

The inner diameter of the 6200 bearing is 10 millimeters. It can accommodate shafts with a diameter of 10 millimeters.

The outer diameter of the 6200 bearing is 30 millimeters. This refers to the diameter of the outer ring of the bearing. Make sure that your application space can accommodate the outer diameter of the 6200 bearing.

The width of the 6200 bearing is 9 millimeters. This refers to the distance between the inner and outer rings of the bearing. Ensure that this dimension is suitable for your application to ensure proper installation and operation.

The 6200 bearing is a common and widely used bearing model. Understanding its inner diameter, outer diameter, and width dimensions is crucial for selecting the appropriate bearing. Based on your application requirements, load, speed, temperature, and quality criteria, choose the suitable size of the 6200 bearing for your application to ensure good performance and reliability.

The 6200 bearing is typically composed of an inner ring, outer ring, ball elements, and a cage. The groove in the raceway is slightly larger than the radius of the steel balls. Due to the point contact between the balls and the raceway, the 6200 bearing can withstand both axial loads in both directions and radial loads. It is commonly used in pairs under normal conditions to minimize the internal axial forces caused by the load and to primarily handle radial loads.

Acting as the stationary raceway, the outer ring completes the race circuit and encapsulates the entire bearing.

These small, spherical elements provide the necessary separation and facilitate smooth rotation.

The sealing covers for the 6200 bearing mainly come in three types: ZZ, 2RS, and OPEN.

6200 OPEN, 6200ZZ, and 6200 RS are different outer cover modes of the bearing. In this article, we will introduce these outer cover modes to help you choose the appropriate bearing protection method that suits your needs.

The 6200OPEN type bearing cover is a design without a cover, allowing the internal components of the bearing to be exposed to the external environment. This design makes the bearing more susceptible to contamination from dirt, dust, and other external particles. Therefore, the 6200 OPEN type bearing is more suitable for applications in clean environments or where regular cleaning is required.

.jpg)

6200ZZ refers to the 6200 bearing with metal shields as the outer cover. The metal shields effectively block dust, contaminants, and other external particles from entering while retaining the lubricant within the bearing.

.jpg)

6200RS refers to the 6200 bearing with rubber seals as the outer cover. The rubber seals provide enhanced protection by effectively blocking moisture, dust, and other contaminants from entering. This sealing method is commonly used in harsh environments and applications that require stricter protection.

When choosing the appropriate bearing outer cover mode for your needs, consider the following factors:

Application environment: Determine the potential sources of contamination and other external particles in your application environment. Based on the environmental conditions, choose between open type, metal shields, or rubber seals to provide the appropriate protection.

Precision and speed requirements: Consider the precision and speed requirements of your application. Open type bearings are typically suitable for low precision and lower speed applications, while metal shields and rubber seals offer higher protection and are suitable for medium and high precision requirements.

Maintenance requirements: Consider your maintenance needs for the bearings. Open type bearings require regular cleaning and lubrication, while metal shields and rubber seals can reduce maintenance requirements.

6200OPEN, 6200ZZ, and 6200RS are different outer cover modes of bearings that provide varying degrees of protection and support. Depending on your application environment, precision and speed requirements, as well as maintenance needs, choose the appropriate outer cover mode to ensure the normal operation of the bearing and extend its lifespan.

Standardized Size: The 6200 bearing is a standard-sized deep groove ball bearing that complies with international standard specifications, making it easy to select and replace.

High Load Capacity: Thanks to its deep groove ball structure, the 6200 bearing exhibits excellent load-carrying capacity, making it suitable for various applications.

High Speed: The internal design of the bearing allows the 6200 to achieve relatively high speeds, making it suitable for high-speed operating machinery.

Low Friction Loss: During operation, the 6200 bearing experiences low internal friction, leading to energy savings and reduced mechanical losses.

Strong Durability: With high-quality materials and precision manufacturing, the 6200 bearing boasts a longer service life, thereby reducing maintenance costs.

Wide Adaptability: The 6200 bearing finds extensive application in various mechanical equipment such as electric motors, gearboxes, automobiles, and agricultural machinery.

The 6200 bearing is a high-performance, durable, and reliable standard-sized deep groove ball bearing, suitable for various mechanical applications with different load and speed requirements.

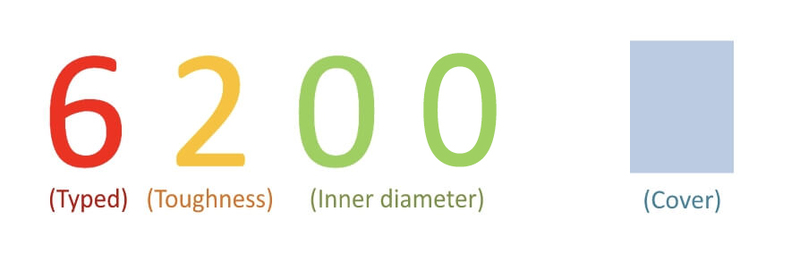

6 --- Single row deep groove ball bearing

2 ---Light

00 --- 10mm

.jpg)

Indicating the sealing or protection method of the bearing. "Z" represents metal shields, and "2Z" represents a bearing with two metal shields.

.jpg)

Indicating the sealing method of the bearing. "R" represents a bearing with a single rubber seal, while "2R" represents a bearing with two rubber seals.

The 6200 bearing is a widely used bearing model in various industries. It boasts excellent design and features, making it suitable for a wide range of high-speed and high-temperature applications. This article will introduce the main application areas of the 6200 bearing, including but not limited to mechanical equipment, power tools, automotive industry, and household appliances.

The 6200 bearing is widely used in mechanical equipment such as machine tools, fans, water pumps, and gearboxes. Its high precision and excellent load-carrying capacity make it a primary supporting component in these mechanical devices.

The 6200 bearing is also widely used in various power tools, such as electric drills, angle grinders, and electric saws. They can maintain stable performance during high-speed operation, ensuring the normal functioning of the tools.

The 6200 bearing plays a crucial role in the automotive industry. They are applied in various components such as wheels, engines, transmissions, and steering systems, ensuring the safety and smooth operation of automobiles.

The 6200 bearing is widely used in household appliances such as washing machines, fans, refrigerators, and more. They can maintain stable operation during extended periods of use and provide reliable support.

The 6200 bearing is also utilized in many other fields, including agricultural machinery, aerospace, and construction equipment. The special requirements of these industries are also met by the 6200 bearing.

The 6200 bearing is a very common and widely used bearing model in multiple industries. Its outstanding features and high performance make it excel in various high-speed, high-temperature, and high-load applications. As a bearing expert, I highly recommend the 6200 bearing and suggest users select the appropriate model and size based on their specific application needs.

Read more:

Read more:

6204 Bearing Dimensions | Deep Groove Ball Bearings

6205 Bearing Dimensions | Deep Groove Ball Bearings

Bearing model numbers consist of three parts:

We previously helped an electromechanical equipment manufacturer in Asia resolve abnormal bearing noise issues. By optimizing the sealing structure and adjusting lubrication parameters, we significantly improved system stability and reduced maintenance costs.

Case reference: ISK BEARING Customer Cases

We offer a range of testing and technical services, including independent heat treatment, automated noise & vibration testing, clearance inspection, salt spray testing, and more — helping our clients improve product reliability and performance.

Resource overview: ISK Technical Resources

You can visit the ISK official FAQ section to explore answers related to bearing selection, product specifications, and more.

FAQ Section: ISK Bearings FAQ Center

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.