Need Support?

Please provide your question. We’ll find you with the best support options.

ISK Bearings | B2B Bearing Wholesale

Table of content

In this article, we’ll be talking about two types of wheel bearings. The general design of the car has been used for two types - rolling and plain bearings. Many tens of thousands of them. Almost all automotive units have bearings.

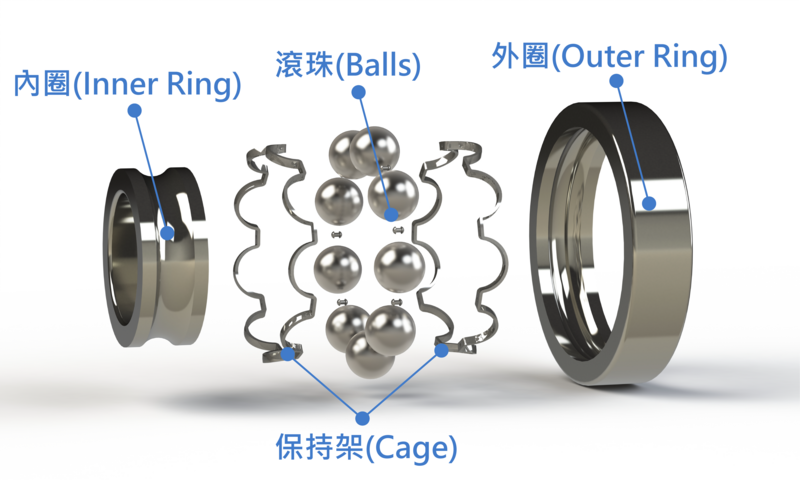

By this type, and refers to the bearing hub. It consists of two rings - outer and inner cage and rolling elements. These "bodies" have different shapes, with rotations or grooves created between the two rings "riding the wind". Depending on the shape of the body of the rolling bearing the hub is still a ball or a roller. In the latter case, the rollers can be of different shapes: cylindrical, needle, conical or any other.

Sliding friction is present during the operation of sliding bearings, and its magnitude is primarily influenced by manufacturing precision. The friction in sliding bearings is mainly determined by the material of the bearing's sliding surface. These bearings typically feature a self-lubricating function on their working surface. Based on materials, sliding bearings are categorized into non-metallic and metallic types.

Non-metallic sliding bearings, primarily composed of high-performance engineering plastics, are commonly known as plastic bearings. Leading manufacturers often employ self-lubricating modification technology for engineering plastics. This involves enhancing the plastics through the addition of fibers, special lubricants, glass beads, etc., to achieve improved self-lubrication and performance. The modified plastics are then processed into self-lubricating plastic bearings using injection molding.

In the early 21st century, the widely used metal sliding bearing is the three-layer composite bearing. This bearing typically utilizes a carbon steel plate as its base. Sintering technology is applied to create a layer of spherical copper powder on the steel plate, followed by another layer of spherical copper powder on top. A thin layer (approximately 0.03mm) of PTFE lubricant is then sintered onto the copper powder layer. The middle layer of spherical copper powder primarily strengthens the bond between the steel plate and PTFE, while also contributing to bearing strength and lubrication during operation.

A precise mechanical component, the rolling bearing transforms sliding friction between the running shaft and the shaft seat into rolling friction, minimizing frictional losses. Rolling bearings generally consist of four parts:

The shape, size, and number of rolling elements directly impact the performance and lifespan of the rolling bearing. The proper functioning of these components collectively contributes to the bearing's efficiency and longevity.

The manufacturing of bearing parts involves specialized equipment, including ball mills and grinding machines for processing steel balls. This specialization extends to the production of bearing components, with dedicated companies focusing on specific aspects. For instance, steel ball manufacturers specialize in producing steel balls, while miniature bearing factories concentrate on manufacturing miniature bearings.

The use of advanced machine tools, tooling and processes is made possible due to the high volume scale requirements of bearing production. Such as CNC machine tools, three-jaw floating chuck and protective atmosphere heat treatment.

.jpg)

Specialization in bearing production facilitates the automation of the manufacturing process. The use of numerous fully automatic and semi-automatic dedicated and non-dedicated machine tools, along with the gradual adoption of automatic production lines, exemplifies this trend. Notable examples include automatic heat treatment lines and automated assembly lines.

With the rear wheel drive of the car it is the following: by type - rollers, according to the number of rows - single column, in the form of rolling elements - conical. The common node is used for two such bearings. They can withstand considerable radial and axial loads.

Read more

Read more

The Comprehensive Guide to Needle Roller Bearings

How to Install Bearings on a Shaft? The Beginner's Guide

Bearing model numbers consist of three parts:

We previously helped an electromechanical equipment manufacturer in Asia resolve abnormal bearing noise issues. By optimizing the sealing structure and adjusting lubrication parameters, we significantly improved system stability and reduced maintenance costs.

Case reference: ISK BEARING Customer Cases

We offer a range of testing and technical services, including independent heat treatment, automated noise & vibration testing, clearance inspection, salt spray testing, and more — helping our clients improve product reliability and performance.

Resource overview: ISK Technical Resources

You can visit the ISK official FAQ section to explore answers related to bearing selection, product specifications, and more.

FAQ Section: ISK Bearings FAQ Center

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.