Need Support?

Please provide your question. We’ll find you with the best support options.

Table of Contents

1. Engineered Plastic Bearings

2. Engineered Plastic Bearing Materials Overview

Key Features of Engineered Plastic Bearings

Light Weight

Corrosion Resistance

Low Friction

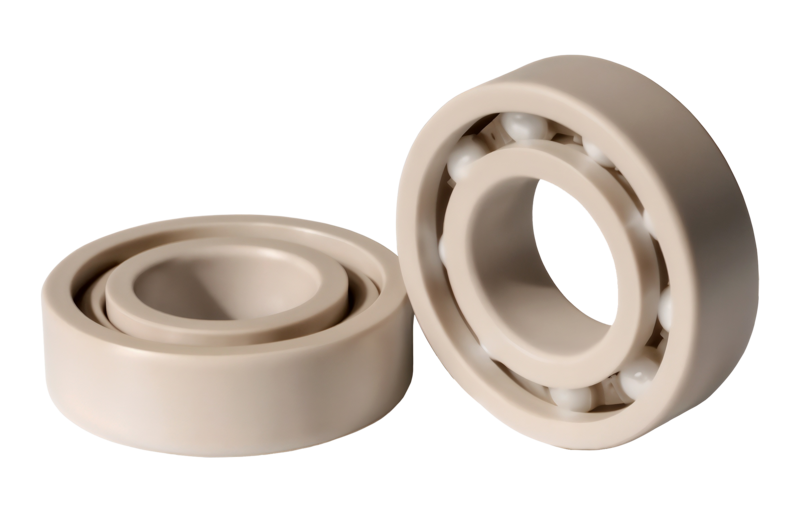

ISK Bearings' engineered plastic bearings are precisely manufactured with inner and outer rings made of POM, PP, PTFE, PVDF, PEEK, and other engineering plastic materials. They can be equipped with Si3N4 ceramic balls, ZrO2 ceramic balls, glass balls, or stainless steel balls, making them suitable for environments requiring precision, corrosion resistance, and oil-free lubrication. The use of these advanced materials bearings new possibilities for bearing performance and industrial equipment applications.

Engineered plastic bearings exhibit a wide range of material properties:

(1) POM (Polyoxymethylene) and PA (Polyamide) offer good mechanical strength and wear resistance, making them suitable for high-temperature environments ranging from approximately -55℃ to 100℃. PP (Polypropylene), HDPE (High-Density Polyethylene), and UPE (Ultra High Molecular Weight Polyethylene) are suitable for most acidic and alkaline environments and possess self-lubricating properties without the need for oil.

(2) PTFE (Polytetrafluoroethylene) and PVDF (Polyvinylidene Fluoride) provide the best chemical resistance.

PEEK (Polyetheretherketone) and PI (Polyimide) are modern engineering plastics with PEEK capable of continuous use at temperatures up to 260℃ and PI up to 300℃. Both have excellent corrosion resistance, making them ideal for complex acidic and alkaline environments.

(1) Additionally, PEEK offers extremely high thermal stability, high rigidity, and hardness.

(2) PTFE is known for its chemical corrosion resistance, low friction coefficient, and excellent electrical insulation properties.

(3) HDPE offers good electrical insulation and is easy to weld, with a working temperature range of -50℃ to +90℃, while PVDF can operate within a temperature range of -60℃ to +150℃.

Save Time, Inquire Now | B2B Bulk and Custom Bearings

Save Time, Inquire Now | B2B Bulk and Custom Bearings

PTFE (Polytetrafluoroethylene) has long-term application temperature from -40°C to 200°C, has very strongly bears chemistry corrosiveness, to all chemicals all anti-corrosive,the friction ceofficient is low,has the good electric,certainly not temperature influence.

The inner and outer rings of precision engineering plastics bearings are usually made with POM and PEEK, rolling elements with glass balls, stainless steel balls and ceramic balls, cages with PA66(strengthened with glassfiber) and PEEK. POM and PEEK materials are suitable for precision processing. The precision and tolerance of plastics bearings made of POM and PEEK are higher than that of traditional plastics bearings. Precise and high speed rotation working conditions are applicable.

Acid/alkali-resistant plastics bearings made with HDPE, PP, UPE, PE-UHMW, provide multiple solutions according to different application conditions. They have impressive resistence to acid, alkali, salt, solution, oil, gas and sea water, and ensure ideal durability and life expectancy.

Corrosion resistant bearings made with PTFE and PVDF are applicable in the environments of strong acid and strong alkali. PTFE can be used in all strong acid and strong alkali even in 98% fuming sulfuric acid and fuming nitric acid.

High temperature resistant bearing is made with PEEK and PI which are tested to be the ideal materials. PI can be used at 300°C in long term and at 350° in short term.

Engineered plastic bearings find application in high-vacuum and high-temperature environments in the semiconductor manufacturing process. They are used to support and operate equipment, ensuring process stability and precision.

Due to their excellent biocompatibility and low friction properties, engineered plastic bearings are widely employed in medical devices such as artificial joints, dental equipment, and medical imaging devices.

Engineered plastic bearings possess exceptional corrosion resistance, making them widely used in corrosive environments found in industries such as chemical manufacturing, marine engineering, and oil extraction.

If you're using bearings in other industries, let us know your application requirements — we'll recommend the most suitable bearings for you.

With IATF 16949, RoHS, and REACH certifications, we adhere to international standards, ensuring that our products not only meet the highest quality standards but are also environmentally friendly.

Need a Reliable Partner for High-Volume and Quality Engineered Plastic Bearings?

Please provide your question. We’ll find you with the best support options.