Need Support?

Please provide your question. We’ll find you with the best support options.

Table of content

2. Investment in Automated Bearing Production Lines

3. Establishment of Industrial Bearing Laboratory

4. Professional Bearing Heat Treatment Technology

5. Rigorous Bearing Metallographic Testing

In the fiercely competitive bearing manufacturing market, our factory has earned the trust and collaboration of international giants through its exceptional technical expertise and rigorous quality control. Here are the key advantages of our factory:

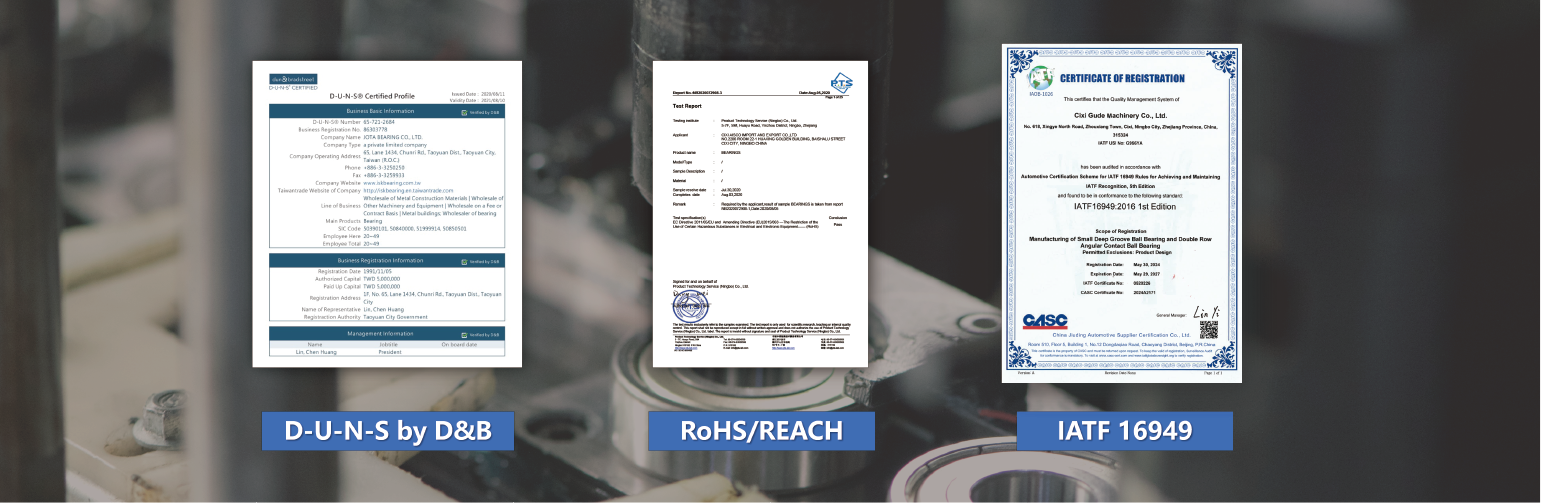

We rigorously monitor production quality and have established a factory in Ningbo certified to IATF 16949 standards, ensuring our bearings meet the highest production quality specifications. Our products comply with environmental safety standards such as RoHS, REACH, and pass SGS inspections, meeting customer requirements for production environments.

We are committed not only to maintaining high-quality bearing supply but also offer professional customized bearing services, industry application consulting, and excellent after-sales service. These advantages have made ISK a preferred bearing brand for several globally renowned manufacturers.

To meet the stringent procurement requirements of international corporate clients, our factory holds ISO/TS 16949 certification, now upgraded to IATF 16949. Given the critical nature of automotive quality for safety and reliability, this standard sets stricter management criteria. Thus, ISK bearings ensure excellent performance even under heavy loads and high-stress environments, meeting the demands of customers with high-quality requirements.

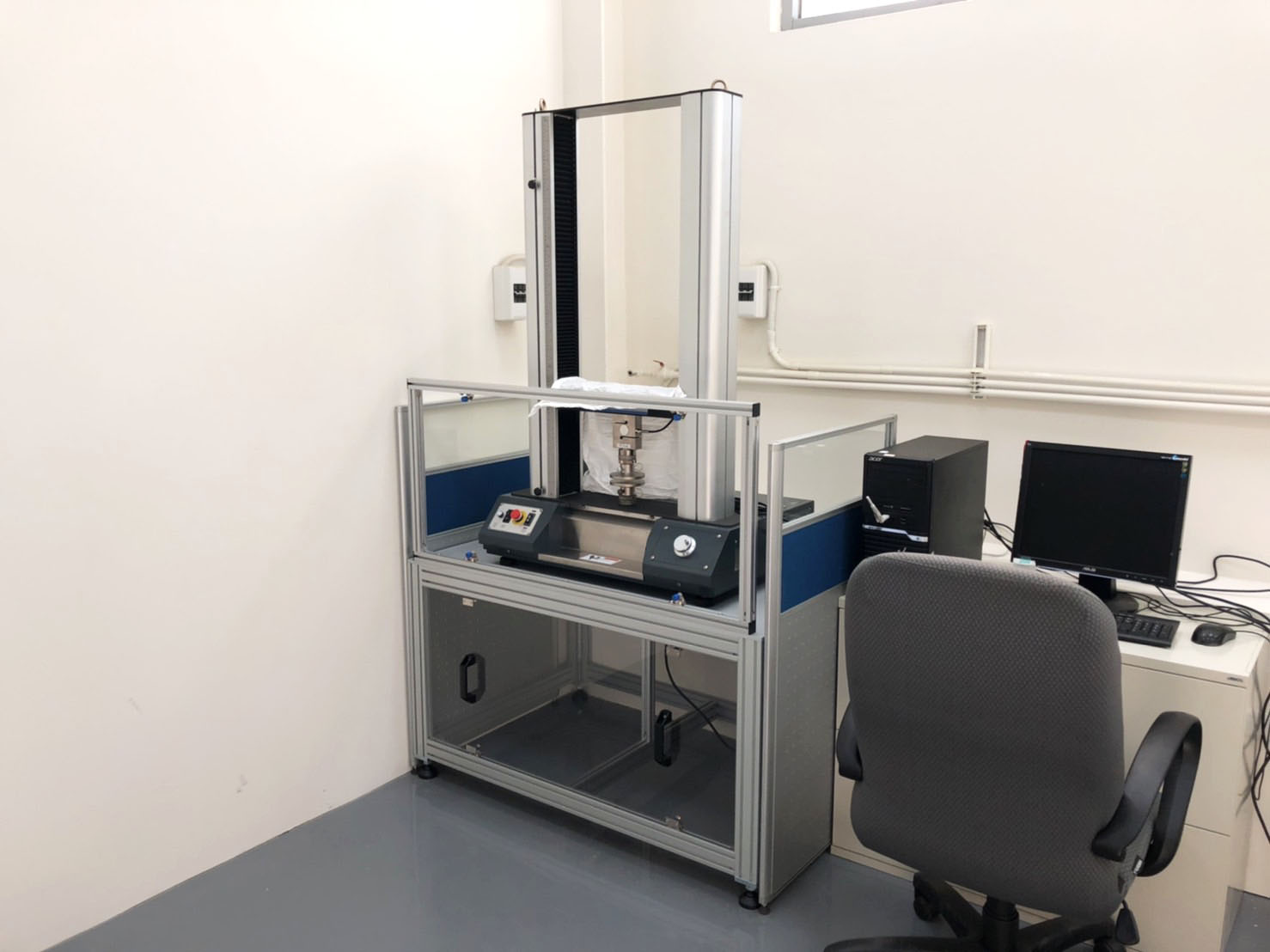

Our headquarters has established a professional industrial laboratory for product development and quality testing. This enables us to conduct precise analysis and improvements during the product design and manufacturing process, continuously enhancing product performance and durability.

▼Bearing Salt Spray Testing Video

We have our own heat treatment plant, where we precisely control the heating and cooling processes. Using an advanced temperature control system, we ensure that the bearings reach the optimal temperature curve during these processes. This technology results in a more uniform and stable internal structure of the bearings, avoiding the common structural inconsistencies found in traditional heat treatment methods.

▼ISK BEARINGS Factory Heat Treatment

Detailed Introduction to Heat Treatment

Detailed Introduction to Heat Treatment

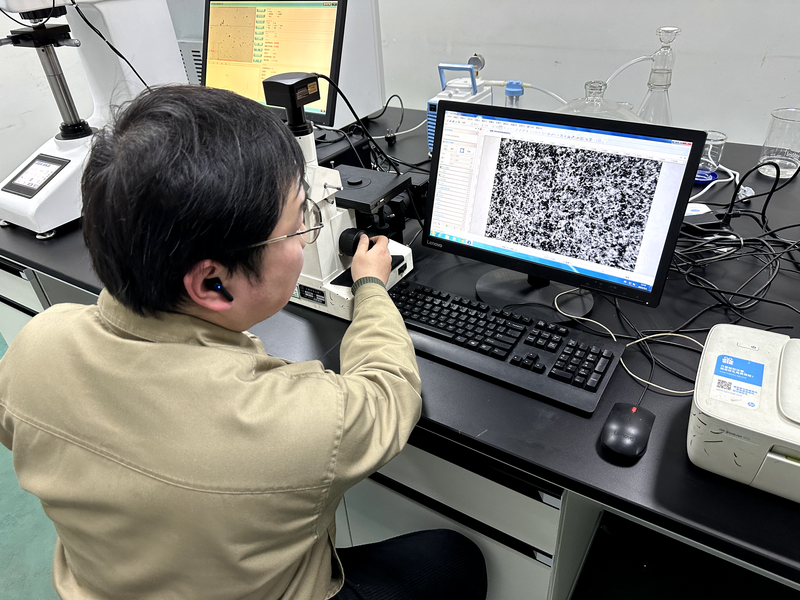

In addition to precise heating and cooling control, we also conduct rigorous metallographic testing to examine the carbon distribution density within the bearings. A uniform carbon distribution significantly enhances the strength and durability of the bearings, ensuring that our products maintain excellent performance under heavy loads and high-stress environments. This, in turn, improves the reliability and operational efficiency of the equipment.

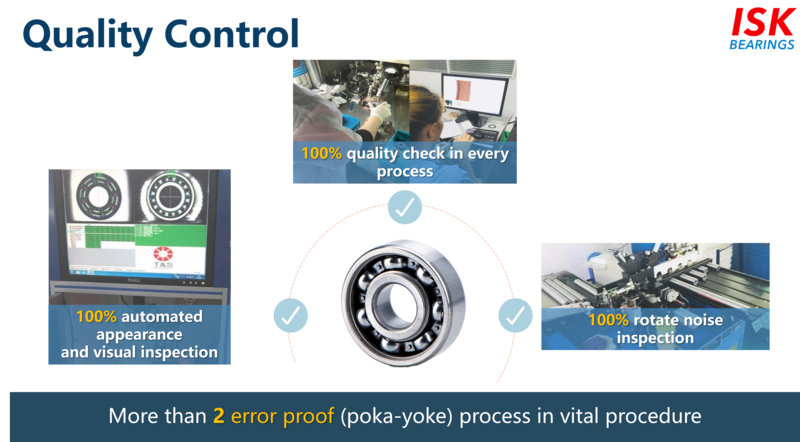

Our bearings undergo rigorous quality testing before leaving the factory, including dimension checks, hardness testing, performance testing, 100% automated visual inspection, and 100% noise testing. To further ensure quality, we have implemented two or more error-proofing (poka-yoke) processes in critical procedures, guaranteeing that every step undergoes 100% quality inspection.

We use advanced automatic noise and vibration detection instruments to rigorously inspect each bearing, meeting various requirements based on noise levels. Additionally, our automated visual inspection equipment precisely checks for dust and defects on bearings.

These inspection technologies offer high precision and reliability, ensuring strict quality control for every bearing. With our bearings tested 100% automatically, you can ensure smoother equipment operation, reduced noise, and significantly lower maintenance and replacement costs due to bearing failures. This enhances overall equipment performance and meets diverse application needs—from standard machinery to high-demand motor equipment, our bearings deliver outstanding performance.

We are equipped with advanced testing equipment, including automated visual inspection, dimensional measurement, vibration and noise detection, hardness testing, groove inspection, surface roughness measurement, salt spray testing, and crush load testing. These facilities ensure the high quality of our products.

With these technological advantages and rigorous quality control, our bearings excel in high-performance machinery, significantly enhancing your operational efficiency and saving substantial maintenance and replacement costs. Choosing us ensures reliable and efficient bearing solutions, enabling smoother equipment operation and higher productivity for your operations.

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.