Need Support?

Please provide your question. We’ll find you with the best support options.

Bicycle bearings are among the key components that support the operation of the entire bicycle. Choosing bearings that are durable and have a long lifespan not only enhances the smoothness of the ride but also reduces maintenance and replacement costs. In this article, I will share several key points to ensure that the bicycle bearings you choose possess outstanding durability and longevity.

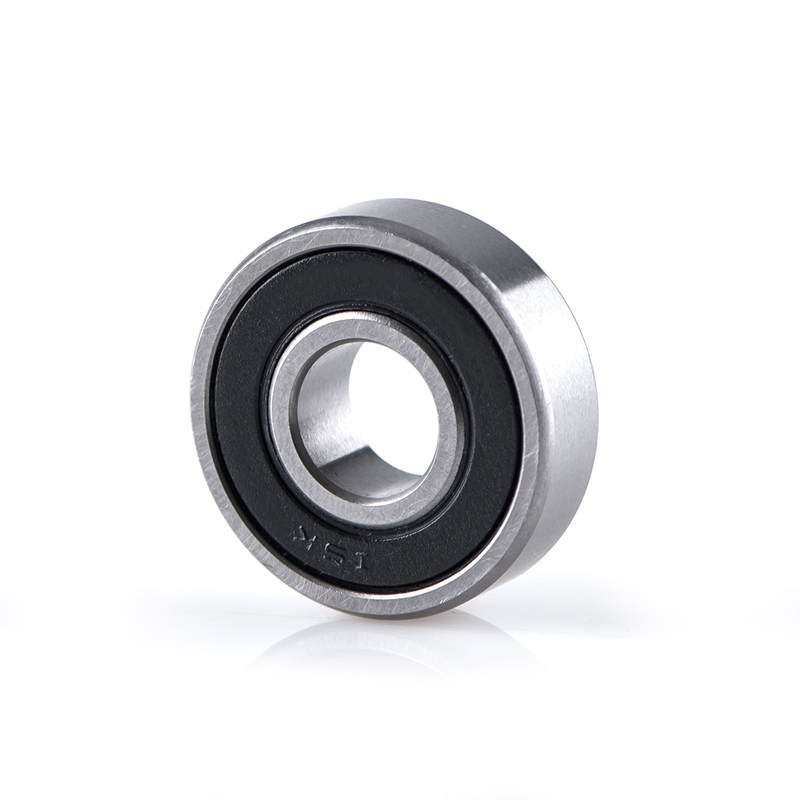

The material of the bearings dictates their durability and corrosion resistance. When selecting bicycle bearings, ensuring the choice of high-quality bearing materials is a pivotal factor in guaranteeing their durability and extended lifespan. Here are some common bearing materials along with their characteristics:

%E4%B8%BB.jpg)

Stainless steel bearings are renowned for their exceptional anti-rust properties, showcasing excellent resistance to water and chemical corrosion. This makes stainless steel bearings suitable for various environments, including damp conditions. Their outstanding wear resistance and high hardness enable them to withstand greater loads while also extending their lifespan.

Ceramic bearings are typically crafted from hard ceramic materials, boasting exceptional hardness and wear resistance. Ceramic bearings not only exhibit lightweight characteristics but also demonstrate low friction and high corrosion resistance, making them an excellent choice for high-performance bicycles.

Further Reading: Disadvantages and Limitations of Ceramic Bearings

.jpg)

Bearing steel is a relatively cost-effective and affordable bearing material, possessing good strength and durability. Although not as corrosion-resistant as stainless steel and ceramics, bearing steel still offers excellent performance under various conditions. Opting for high-quality bearing steel ensures its stable operation under common riding conditions.

Certain bearings might incorporate specialized surface coatings to offer added wear resistance and corrosion protection. These coatings are often intricately designed to effectively reduce friction and wear, thereby extending the bearing's lifespan.

When selecting bearing materials, you should consider factors such as riding conditions, expected loads, environment, and budget. Stainless steel, ceramics, and bearing steel are common choices, each with distinct characteristics that can be chosen based on your needs. Regardless of the material you choose, ensure selecting high-quality and reputable manufacturers to guarantee the durability and longevity of the bearings.

Common Electric Bicycle Bearing Materials

Bearing sealing and protection can effectively isolate external dust, moisture, and contaminants, thereby reducing wear and damage. When it comes to ensuring the durability and long lifespan of bicycle bearings, sealing and protection are crucial factors.

Here are some common methods of bearing sealing and protection, along with their functions and features:

%201688.jpg)

ZZ

Metal covers are typically made from stainless steel or bearing steel, offering good corrosion resistance and strength. These covers effectively isolate the entry of dust, moisture, and contaminants, safeguarding the interior of the bearing from external environmental factors. The advantages of metal covers include durability, allowing them to maintain stability under various harsh conditions.

.jpg)

Rubber seals are a common sealing method that can effectively prevent the infiltration of dust, moisture, and contaminants. Rubber seals possess excellent elasticity, allowing them to snugly fit into the space between the bearing and the external environment. This sealing method excels in protecting the bearing from contamination and damage.

Choosing the appropriate sealing and protection method depends on your riding conditions and environment. If you frequently ride in wet or dusty areas, selecting bearings with effective sealing technology is crucial. Similarly, considering your usage scenarios, opt for suitable covers and protection methods to ensure the bearings can maintain stable and durable operation in various environments.

Function and Selection Guide for Electric Bicycle Bearing Covers

The load that bearings endure affects their lifespan. Ensure that the selected bearings can handle the expected load to avoid excessive damage. Moreover, regular lubrication is crucial. Choosing the appropriate lubricant guarantees the smoothness and durability of bearing operation.

What factors should be considered when choosing bearing lubricants?

Performing regular maintenance and inspections on the bicycle's bearings helps to detect issues early and take appropriate measures. Ensuring that the bearings are in good condition can reduce unnecessary damage and replacements.

When choosing bicycle bearings, durability and lifespan are critical considerations. By selecting high-quality materials, excellent sealing techniques, appropriate loads and lubrication, as well as performing regular maintenance and inspections, you can ensure that the chosen bearings maintain superior performance over long-term riding. Opting for a reliable manufacturer allows you to enjoy a smoother and more dependable cycling experience.

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.