Need Support?

Please provide your question. We’ll find you with the best support options.

Table of content

1. Precise control of heating and cooling processes

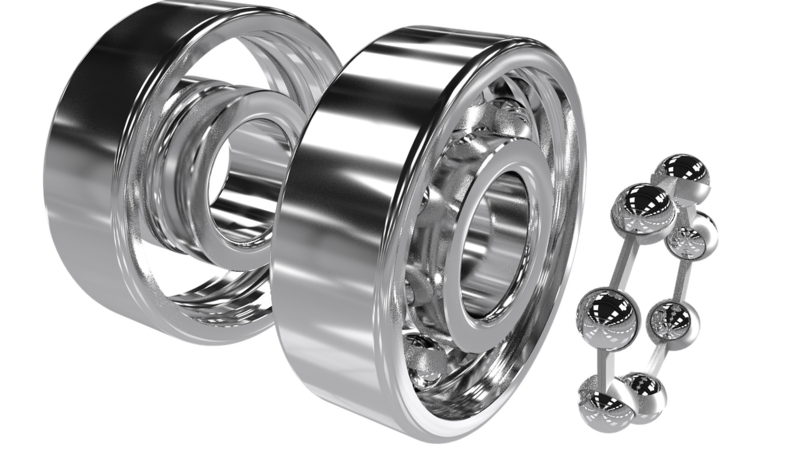

In modern industry, bearings are essential core components of mechanical equipment, with their lifespan and performance crucial to overall operational efficiency.

ISK is committed to enhancing the quality and durability of bearings.

ISK's heat treatment technology is characterized by precise control over the heating and cooling processes. This technology utilizes a sophisticated temperature control system to ensure that bearings achieve the optimal temperature profile during heating and cooling.

This approach results in a more uniform and stable internal structure of the bearings, addressing common issues of uneven structure often found in traditional heat treatment methods.

In addition to precise heating and cooling control, ISK conducts rigorous metallographic testing. This type of testing evaluates the carbon distribution density within the bearings, ensuring uniform carbon distribution in each bearing.

The uniformity of carbon distribution is a key indicator of heat treatment quality, significantly enhancing the strength and durability of the bearings.

Through ISK's heat treatment technology, the strength and durability of bearings are significantly enhanced. These bearings maintain excellent performance even under heavy loads and high stress conditions, ensuring higher reliability for your equipment. With reduced maintenance and replacement frequency, substantial costs are saved while improving overall operational efficiency.

.png)

.png)

ISK bearings undergo rigorous quality testing before leaving the factory to ensure each product meets our highest standards. These tests include dimension checks, hardness testing, and performance evaluations. Through these stringent quality control measures, our bearings demonstrate excellent performance in high-performance mechanical operations, thereby enhancing your long-term production efficiency.

In conclusion

ISK's heat treatment technology not only significantly enhances the strength and durability of bearings but also greatly extends their lifespan. The application of this technology ensures more reliable operation of your equipment, reduces maintenance and replacement frequency, thereby saving costs and improving overall operational efficiency. Choosing our bearings means opting for high quality, high performance, and long-term benefits.

ISK is committed to innovation and technological advancement to provide customers with the best bearing solutions, ensuring smooth and efficient operation of your equipment. We appreciate your trust and support in our products.

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.