Need Support?

Please provide your question. We’ll find you with the best support options.

INQUIRE NOW

INQUIRE NOW

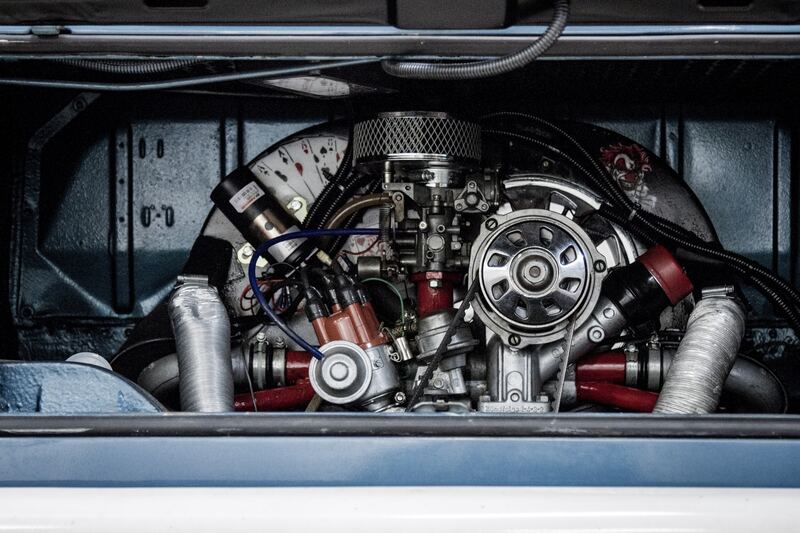

From heavy machinery to delicate instruments, steel bearings are integral components that enable the seamless rotation of shafts and axles. In this article, we will delve into the world of steel bearings, exploring their advantages, applications, and how they compare with other bearing types.

.jpg)

Steel bearings are engineered with precision, crafted from high-quality steel alloys. Their robust construction makes them resistant to wear and tear, ensuring durability and longevity. These bearings find their applications in an array of industries, including automotive, aerospace, manufacturing, and robotics, owing to their exceptional load-bearing capacity and resistance to high temperatures and harsh environments.

| Bearing Type | Advantages | Limitations |

|---|---|---|

| Steel Bearings | High load-bearing capacity | Not resistant to corrosion |

| Ceramic Bearings | Lightweight, corrosion-resistant | Lower load-bearing capacity |

| Plastic Bearings | Low friction, corrosion-resistant | Not suitable for heavy-duty applications |

Steel bearings stand as pillars of strength in the realm of industrial machinery, offering unparalleled durability, precision, and versatility. While other bearing types have their unique advantages, steel bearings remain unmatched in heavy-duty applications, providing the backbone for countless industries. Their ability to withstand extreme conditions and heavy loads cements their status as indispensable components in the world of engineering and manufacturing. As technology continues to advance, steel bearings will undoubtedly play a vital role in shaping the future of industries worldwide.

Further Reading:

Further Reading:

Motor Bearings: Types and Functions

Rolling Bearings: Types and Applications

Please provide your question. We’ll find you with the best support options.