Learn more:

Learn more:

ISK Bearings | B2B Bearing Wholesale

ISK Bearings | B2B Bearing Wholesale

Table of contents

Motor bearings are essential components in the world of machinery, responsible for enabling smooth rotational motion while reducing friction. Found in a wide range of applications, from automotive engines to industrial equipment, motor bearings are vital for maintaining the efficiency and reliability of these systems. In this article, we'll take an in-depth look at motor bearings, including their various types and primary functions.

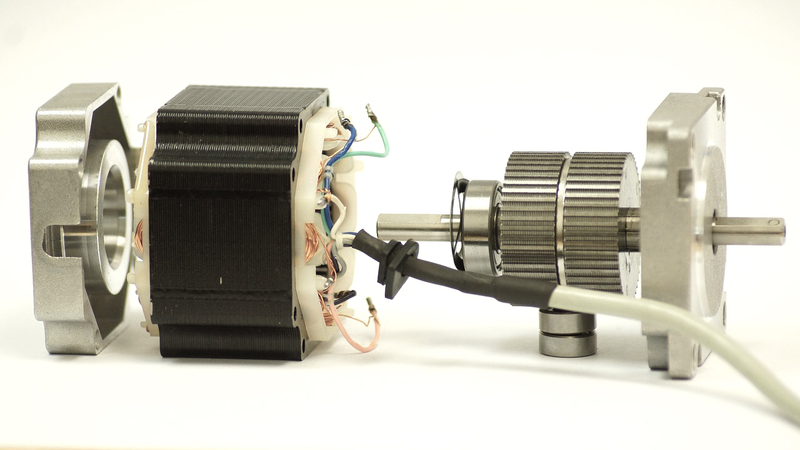

Motor bearings are mechanical devices designed to support the rotational movement of shafts or axles while minimizing friction. They consist of two concentric rings—a stationary outer ring and a rotating inner ring. Between these rings, rolling elements, such as balls or rollers, are positioned to facilitate smooth rotation.

Summary

• Motor bearings are mechanical devices that enable smooth rotation while minimizing friction

• They are structured with inner and outer rings, and rolling elements (balls or rollers)

• Their primary functions are supporting loads and maintaining precise shaft alignment

• Key types include Ball, Tapered Roller, Thrust, and Sleeve bearings

Ball bearings utilize spherical rolling elements (balls) to reduce friction. They are versatile and widely used in devices like electric motors, fans, and automotive components.

Tapered roller bearings use cylindrical or tapered rolling elements (rollers) to distribute loads evenly. They excel in applications where heavier loads must be supported, such as conveyor systems and industrial machinery.

Thrust bearings are specialized for handling axial (thrust) loads and are commonly found in gearboxes, helicopter rotors, and axial fans.

Sleeve bearings, also known as plain bearings, feature a simple cylindrical design without rolling elements. They are often utilized in situations where there are space limitations and reciprocating movement is in play.

Electric bicycles commonly use ball bearings for their motors. This type of bearing excels in high-speed rotation applications, effectively reducing friction to ensure smoother operation. Motor bearings typically feature sealing or dust-proof designs to prevent dust and other impurities from entering, thereby extending the bearing's lifespan and enhancing performance.

Reducing Friction

By facilitating smooth rolling motion, bearings reduce friction between moving parts, minimizing wear and heat generation.

Motor bearings are fundamental components in the machinery that drives our world. Understanding their types, functions, and the importance of proper maintenance is crucial for engineers, mechanics, and anyone involved in machinery operation and upkeep. By maintaining motor bearings effectively, we can ensure the continued efficiency and reliability of the systems they support.

Learn more:

Learn more:

Navigating the World of Industrial Bearings: A Comprehensive Guide Introduction

Bearing model numbers consist of three parts:

We previously helped an electromechanical equipment manufacturer in Asia resolve abnormal bearing noise issues. By optimizing the sealing structure and adjusting lubrication parameters, we significantly improved system stability and reduced maintenance costs.

Case reference: ISK BEARING Customer Cases

We offer a range of testing and technical services, including independent heat treatment, automated noise & vibration testing, clearance inspection, salt spray testing, and more — helping our clients improve product reliability and performance.

Resource overview: ISK Technical Resources

You can visit the ISK official FAQ section to explore answers related to bearing selection, product specifications, and more.

FAQ Section: ISK Bearings FAQ Center

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.