Need Support?

Please provide your question. We’ll find you with the best support options.

Thin section bearings, also referred to as thin wall bearings, represent a specialized category of bearings renowned for their exceptional performance in applications where space and weight considerations are critical. With their thin cross-sections and compact dimensions, these bearings have proven to be ideal solutions for installations with limited available space. In this comprehensive article, we will delve into the world of thin section bearings, exploring their various types, unique characteristics, and diverse applications across a range of industries.

.jpg)

.jpg)

The use of small outer diameter steel balls can reduce friction significantly, it is high rigidity and provides good rotational accuracy.

The thin section bearings with large bores and small cross-sections can use the large-diameter hollow shafts to replace small-diameter solid shafts, which use hollow shafts to ensure space for light weight and wiring.

The covers of thin section bearings primarily come in three distinct types: ZZ, 2RS, and OPEN.

Each type is designed to cater to specific environmental and sealing requirements.

OPEN type features unshielded bearings, offering maximum accessibility but without protective seals.

.jpg)

The ZZ designation indicates shielded bearings, providing protection against contamination and debris ingress.

.jpg)

The 2RS denotes bearings fitted with rubber seals on both sides, ensuring enhanced sealing against moisture and other contaminants.

Thin section bearings exhibit distinct characteristics that set them apart from conventional deep groove ball bearings. Notably, each series of thin section bearings is designed with a fixed cross-section size that does not increase proportionally as the inner diameter expands. This design feature ensures consistency in performance and dimensional stability across various sizes.

One of the key attributes of thin section bearings lies in their use of small outer diameter steel balls, which significantly reduces friction. This results in enhanced rigidity and superior rotational accuracy, making them ideal for applications demanding precision and efficiency.

Thin section bearings possess several key characteristics that make them highly desirable in specific applications

Thin section bearings are engineered with lightweight materials and optimized designs, resulting in reduced overall weight. This makes them suitable for applications where weight reduction is crucial, such as aerospace and automotive industries.

These bearings are manufactured to strict tolerances, ensuring excellent precision and rigidity. This characteristic is vital in precision machinery, medical equipment, and measurement instruments.

Thin section bearings are designed to minimize friction and energy loss, resulting in improved efficiency. This makes them suitable for applications where high performance and energy efficiency are essential, such as industrial machinery and conveyor systems.

Thin section bearings find application in a wide range of industries that require space-saving solutions and precise performance. Some notable industries include

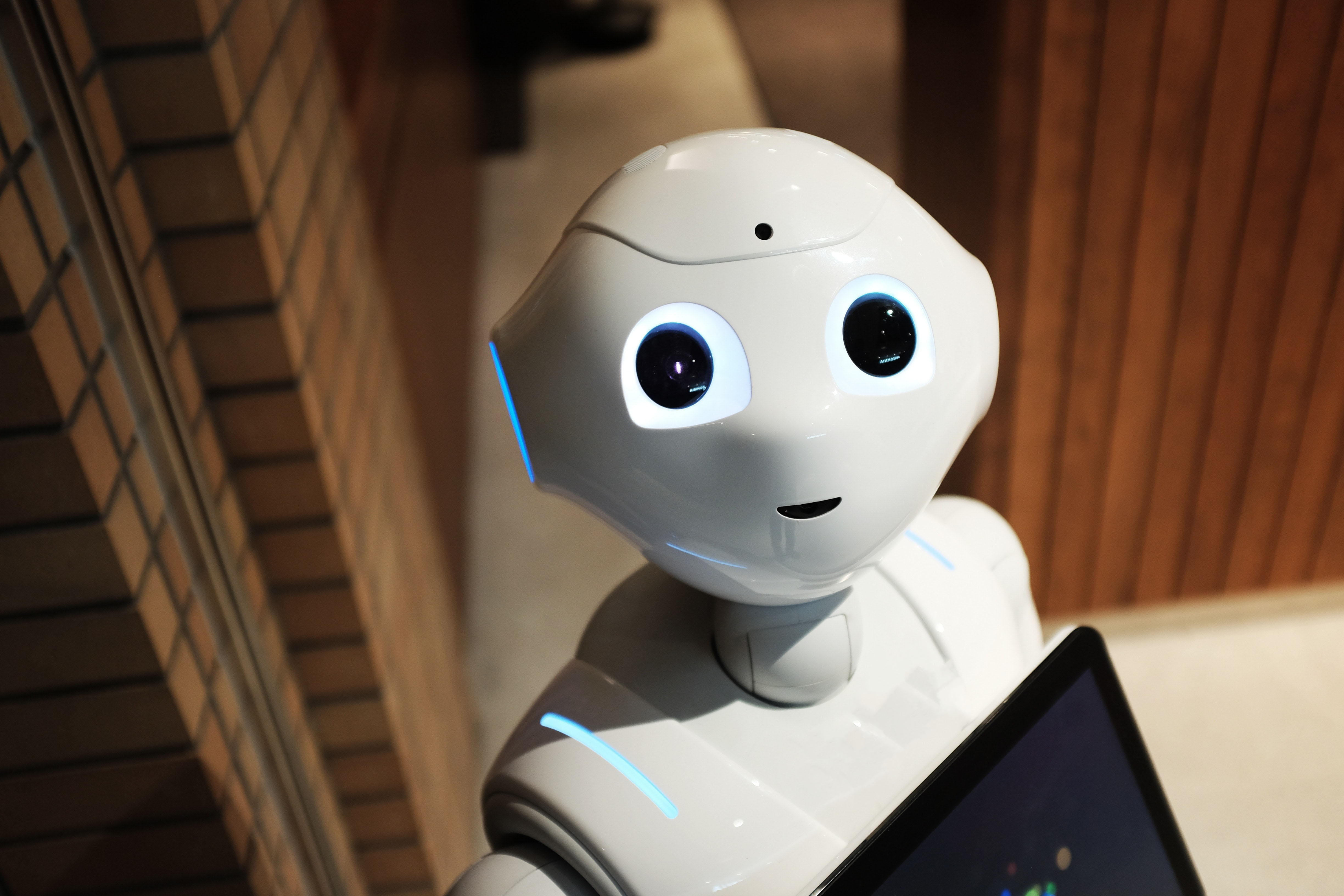

Robotics and Automation

Thin section bearings are extensively used in robotic arms, joints, and other motion control systems. Their compact design and high precision allow for efficient and accurate robotic movements.

Aerospace and Aviation

In the aerospace industry, thin wall bearings are employed in aircraft landing gear, wing flaps, and control mechanisms. Their lightweight construction and high load-bearing capacity make them suitable for critical aircraft applications.

Medical Equipment

Thin section bearings are utilized in medical imaging equipment, surgical robots, and other medical devices. Their compact size and high precision contribute to the reliable operation of these crucial medical applications.

Precision Machinery and Instrumentation

Thin section bearings are commonly found in precision machinery, such as CNC machines, optical equipment, and measuring instruments. Their high rigidity and low friction properties ensure accurate and smooth operation.

Thin section bearings are invaluable components in industries where space optimization, weight reduction, and precision performance are crucial. Their compact design, lightweight construction, and high precision make them ideal for a wide range of applications, including robotics, aerospace, medical equipment, and precision machinery. As the demand for compact and efficient solutions continues to grow, thin wall bearings play an increasingly vital role in enabling innovation and pushing the boundaries of engineering possibilities.

Further Reading:

Further Reading:

Types of Bearings|Different Bearing Varieties

Needle Bearing Size Chart|Teach you how to choose bearings correctly

Ball Bearing Specifications: Detailed Analysis of Structure, Working Principles, and Types

Please provide your question. We’ll find you with the best support options.