- Sleeve Bearings Basic Introduction

- Factors of Sleeve Bearing Wear

- The Importance of Lubricating Grease

- Time to Prepare Your Bushings!

Before learning how do bushings work, let us first have a general understanding of the characteristics of the Sleeve bearing.

From the previous article - Sleeve bearing v.s. Bushing, we learned the following key points:

(1) How do Bushings Works

- Sleeve bearing features are high load-carrying capacity, very inexpensive, compact, and lightweight.

- Sleeve bearings are characterized by ensuring linear or rotational movement between two parts.

- They are used to constrain, guide, or reduce friction in rotary or linear applications.

(2) Composition

- Sleeve bearings consist of one part that is built up of many types of materials, layered, and combined into a load-carrying system to provide smooth operation and greater durability.

- Bushings are also known as sleeve bearings, bushing bearings, plain bearings, self-lubricating bearings, or journal bearings.

Proper installation of a bushing can really make a difference in how everything else in the drive system performs. If it’s installed wrong, you might end up with vibrations, uneven rotation, or even damage to the other parts. This can lead to longer downtime, and if the mating shaft gets damaged, it could turn into a much bigger and more expensive problem.

Therefore, we should first understand the Factors of sleeve bearing wear before we install the bearings to avoid the following situations.

※The following images are for demonstration purposes only and do not represent actual conditions.

(1) Process and Lubricant Issues

- Abrasive wear. (If the wear is caused by a hard particle rubbing between the lubricated surfaces, it is called three-body wear. Wear caused by an asperity on one surface cutting the other surface is called two-body abrasion.)

- Insufficient volume of lubricant.

- Overheated lubricant (viscosity at operating temperature cannot support the load causing frictional heat and additional oil thinning.)

(2) Process and Installation Issues

- Rough surfaces (asperities on the journal cause rubbing.)

- Imbalance (improper loading of the support element causing shock loading.)

- Journal eccentricity (egg-shaped journal causing rubbing on the high spots.)

- Metal fatigue from improper metallurgy.

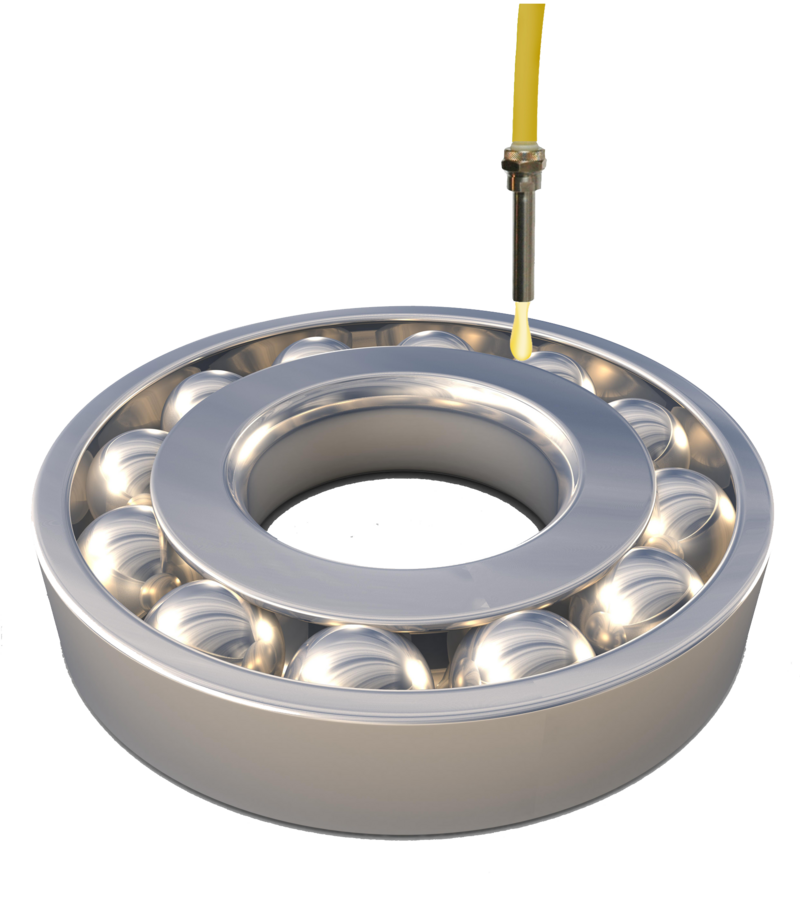

Before installing bushing bearings, it's important to understand lubricating grease and its role in their performance.

- Self-lubricating bearings work by injecting lubricant—either liquid (oil) or solid (like graphite, MoS2, or lead)—into the bearing’s sliding layer. The lubricant is released through pores in the layer to reduce friction, keeping the bearing surface smooth and functional. Even as the sliding layer wears down, the lubricant is evenly distributed, maintaining low friction performance.

- For sleeve bearings, oil is typically used for lubrication. However, grease may be used for slow-speed equipment or when the bearings are hard to access or experience frequent starts and stops. Proper lubrication is key for supporting heavy loads in sleeve bearings. Speed, surface area, viscosity, and oil volume must be balanced for optimal performance. If any of these factors change, the lubricant's viscosity should be adjusted accordingly.

- When selecting lubricants for sleeve bearings, factors such as oxidation stability, corrosion resistance, wear protection, and water separation properties are important. There isn’t a one-size-fits-all approach, as the right lubricant depends on the equipment and operating conditions.

- Grease needs to be continuously replenished in the bearing's dynamic clearance spaces to maintain proper lubrication. For equipment with poor sealing, heavier grease may be required and replenished more frequently. The frequency and volume of grease application depend on operating conditions, grease quality, and how often maintenance can be done.

- When choosing grease, it's important to consider the oil's viscosity, the thickener type, oxidation and rust resistance, consistency, and load-bearing properties. For heavy-duty applications, solid additives like molybdenum disulfide or graphite are added to prevent metal contact and ensure smooth operation under high load and slow speeds.

Let us follow these steps for proper installation:

- First, make sure your shafting is within tolerance.

- Remove all dust, dirt, paint, oil, and grease. (Bushings work through friction and force, so foreign matter on any of these surfaces will inhibit the ability to work correctly.)

- Insert the bushing into the component hub and align the bushing’s non-threaded holes to its counterpart’s threaded ones. The threaded holes on the bushing will be utilized during removal. *QD bushings can be mounted two ways, standard or reverse mount.

- Insert the bolts through the bushing’s non-threaded hole then thread into your counterpart by hand, leaving the assembly loose.

- Install the key onto the shaft and mount assembly as desired. Tighten the setscrew over the key to keep it in place once final drive alignments are complete.

- Alternate tightening your bolts gradually until specific torque values are reached. This progressive tightening allows the bushing to seat correctly and squarely.

Bearing Bushing Size Charts

Read more:

Read more:

What are Ball Bearings Made of?

How Ball Bearing Works? Tell You the Operating Principle

Why is ISK BEARINGS frequently chosen as the specified bearing brand by major international companies?

This is just the tip of the iceberg!

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

Read the Full Article

Read the Full Article

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Read the Full Article

Read the Full Article

TOP

TOP

Read more:

Read more: