Need Support?

Please provide your question. We’ll find you with the best support options.

Table of content

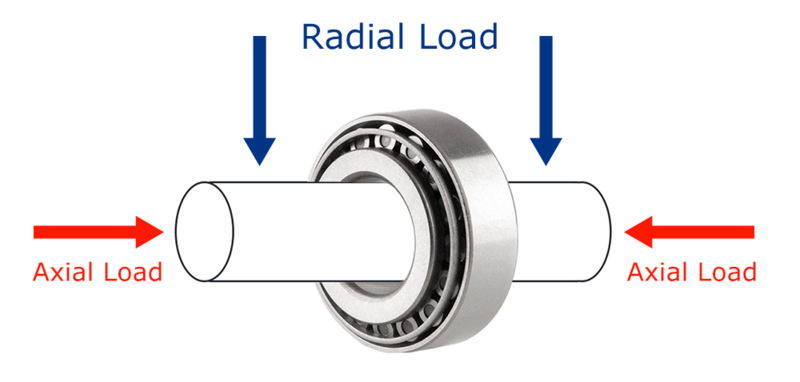

Tapered roller bearings are rolling-element bearings designed to support both radial and axial loads. Their distinctive conical shape, with inner and outer raceways and rollers forming a cone, enables them to transmit radial and axial forces in a specific direction. This makes them perfect for applications with combined load requirements.

Tapered roller bearings showcase engineering precision with their four main components: the cone (inner ring), cup (outer ring), tapered rollers, and a cage to guide and retain the rollers. The tapered geometry of the rollers ensures line contact with the raceways, promoting even load distribution and minimizing stress concentrations.

One of the key advantages of tapered roller bearings lies in their ability to handle both radial and axial loads by virtue of their tapered design. This feature allows for efficient transmission of forces, making these bearings well-suited for applications where heavy radial and axial loads occur simultaneously. The tapered shape also facilitates easy adjustment of the bearing clearance during installation, ensuring optimal performance.

Extended reading: Features and Applications of Tapered Roller Bearings

Extended reading: Features and Applications of Tapered Roller Bearings

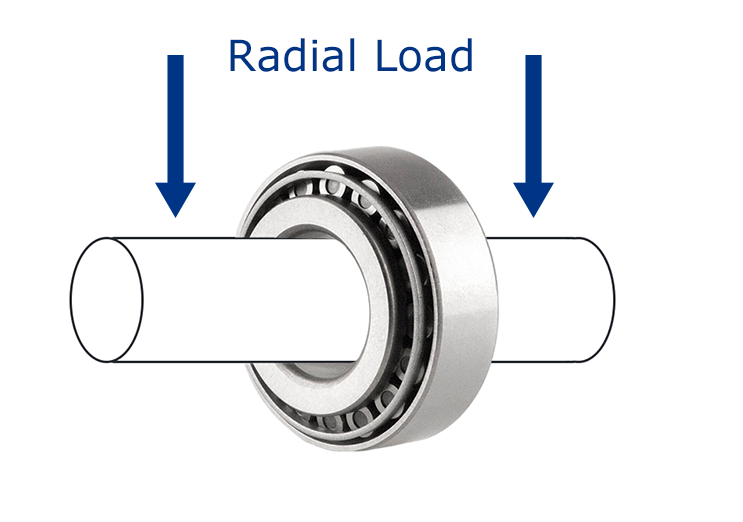

Radial loads are forces applied perpendicular to the axis of rotation, exerted in a direction that is generally towards or away from the center of the bearing. In simpler terms, radial loads act perpendicular to the shaft, causing the shaft to bend or deform. Examples of radial loads include the weight of a rotating shaft, the force exerted by a pulley, or the pressure applied by a belt.

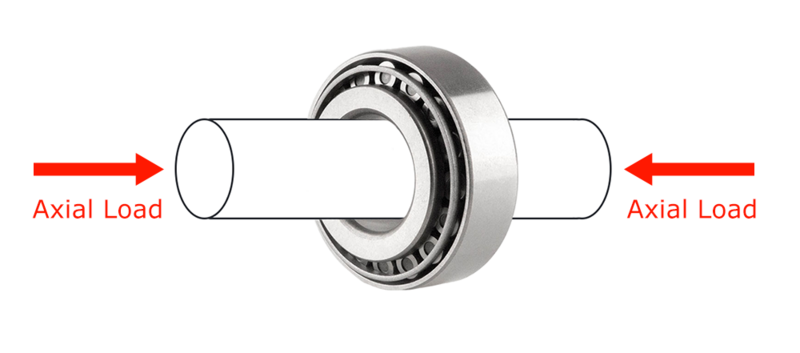

Axial loads, on the other hand, are forces applied parallel to the axis of rotation. These forces act in the same direction as the shaft and can cause the bearing to move along the axis or deform. Examples of axial loads include thrust forces in gear systems, belt tension, or the force applied by a hydraulic cylinder.

The tapered design of roller bearings makes them uniquely suited to handle both radial and axial loads simultaneously. The cone and cup geometry of tapered roller bearings allows them to efficiently distribute these loads along the tapered surfaces. The load-carrying capacity is significantly enhanced as compared to bearings with a purely radial or axial design.

Tapered roller bearings are used in various industries, including automotive, aerospace, heavy machinery, and industrial equipment. In automotive applications, they support wheel hubs, transmissions, and differentials, ensuring smooth vehicle operation. In industrial settings, these bearings help support heavy machinery components that experience varying loads and speeds.

Tapered roller bearings are widely used in automotive applications, especially in wheel hubs. They efficiently handle the radial load from the vehicle's weight and the axial load generated during turns and acceleration.

In industrial machinery, gearboxes experience both radial and axial loads due to the gears transmitting power. Tapered roller bearings excel in such environments, ensuring smooth operation and longevity.

Aircraft components, such as landing gear assemblies, encounter complex loads during takeoff, landing, and in-flight. Tapered roller bearings are chosen for their ability to withstand the diverse forces in these critical applications.

Heavy machinery, like excavators and loaders, often operates under substantial radial and axial loads. Tapered roller bearings contribute to the robustness and reliability of these machines.

Cylindrical roller bearings and tapered roller bearings are two distinct types of rolling element bearings, each designed for specific applications.

In summary, the choice between cylindrical and tapered roller bearings depends on the specific requirements of the application, especially in terms of the types and magnitudes of loads the bearing will experience.

Extended reading:

Extended reading:

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.