2.Key Components and Concepts

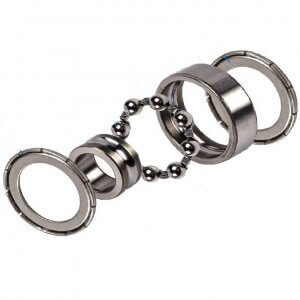

Electric motor bearings consist of several key components:

(1). Inner and Outer Rings

Electric motor bearings consist of an inner ring attached to the motor shaft and an outer ring that houses the rolling elements.

(2). Rolling Elements

These can be balls or rollers, designed to reduce friction between the rings while enabling smooth rotation.

(3). Cage or Retainer

A cage holds the rolling elements in place, preventing them from coming into direct contact with each other, which could cause friction and wear.

%201688.jpg)

(4). Seals or Shields

Electric motor bearings often feature protective seals or shields to prevent contaminants from entering and to retain lubrication.

3.Advantages of Electric Motor Bearings

Electric motor bearings offer several advantages:

(1). Efficiency

By minimizing friction, electric motor bearings contribute to the overall efficiency of electric motors, reducing energy consumption and heat generation.

(2). Reliability

These bearings are essential for the long-term reliability of electric motors, ensuring consistent performance and extended operational life.

(3). Quiet Operation

Electric motor bearings operate quietly, making them suitable for noise-sensitive applications such as HVAC systems and appliances.

(4). Low Maintenance

Properly lubricated and sealed bearings require minimal maintenance, reducing downtime and maintenance costs.

4.Types of Electric Motor Bearings

There are two primary types of bearings commonly used in electric motors:

.jpg)

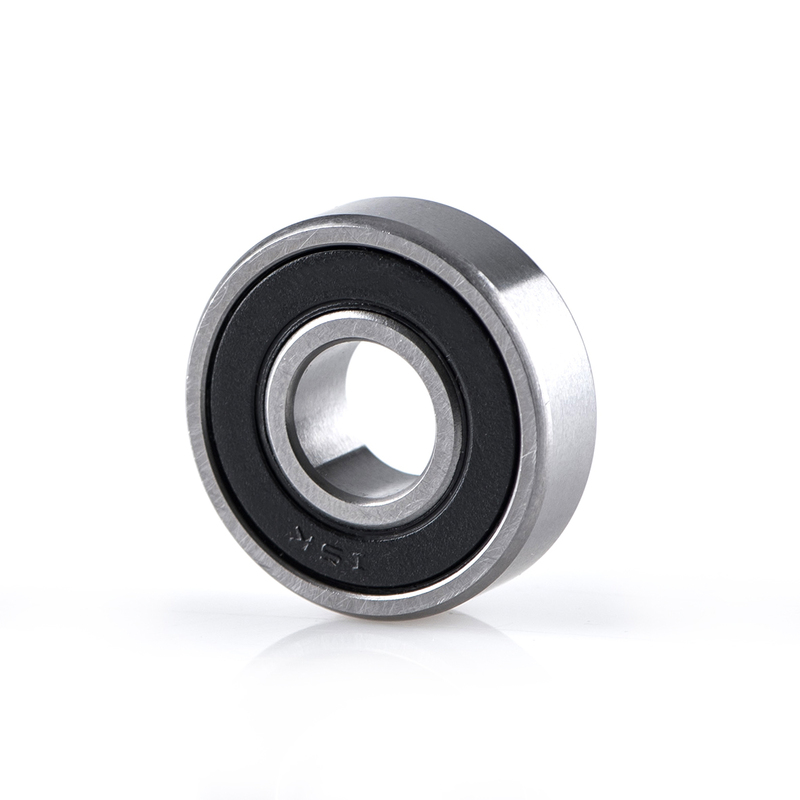

(1). Ball Bearings

Ball bearings consist of spherical rolling elements (balls) placed between the inner and outer rings. They are known for their high-speed capabilities and versatility.

.jpg)

(2). Roller Bearings

Roller Bearings: Roller bearings use cylindrical or tapered rolling elements (rollers) to distribute the load evenly. They are often preferred for applications with heavy radial loads.

Electric motor bearings play a pivotal role in powering our technological advancements, from the industrial sector to our everyday lives. Their ability to minimize friction, enhance efficiency, and ensure reliability makes them a cornerstone of modern machinery and devices.

Investing in high-quality electric motor bearings not only improves the performance and longevity of electric motors but also contributes to energy savings and sustainability. Whether you're designing industrial equipment, automotive systems, or household appliances, understanding and selecting the right electric motor bearings are essential steps toward powering efficiency and innovation.

Further Reading:

Further Reading:

INQUIRE NOW

INQUIRE NOW%20%E6%96%B06011%E4%B8%BB.jpg)