Need Support?

Please provide your question. We’ll find you with the best support options.

Table of Contents

Bushings (also called plain bearings or sleeve bearings) are cylindrical components that reduce friction between moving parts. Key advantages include:

This guide covers bushing functions, material selection, applications across automotive/industrial/agricultural sectors, and selection criteria based on PV values.

They are indispensable key components in mechanical equipment. Typically made from metal or non-metal materials, they are thin-walled hollow cylinders. The primary function of bushings is to support and guide the rotational or sliding motion of the shaft, reducing friction and wear, thereby extending the service life of mechanical equipment.

Bushings play a crucial protective role in various mechanical equipment, specifically in the following aspects:

Bushings play a crucial protective role in various mechanical equipment, specifically in the following aspects:

(1) Reducing Friction:

The use of bushings reduces friction between the shaft and the bearing housing, protecting mechanical components and extending the lifespan of the equipment.

(2) Reducing Vibration:

Bushings have good shock-absorbing properties, effectively reducing vibration during equipment operation and enhancing operational stability.

(3) Reducing Noise:

Bushings can effectively reduce noise generated during equipment operation, improving the comfort of the working environment.

(4) Ease of Maintenance:

Bushings have a simple structure and are easy to replace, lowering maintenance costs and downtime for the equipment.

(5) Simplifying Structure:

The use of bushings can simplify the design and manufacturing process of mechanical equipment.

Understanding the Principles and Specifications of Self-Lubricating Bearings

The materials for bushings are diverse, including soft metals, rubber, nylon, and non-metallic polymers. These materials are relatively soft and cost-effective.

In various harsh working environments, bushings can withstand vibration, friction, and corrosion, protecting the enclosed components. Bushings themselves are easy to replace when damaged and are cost-effective, offering good economic value.

If you need help selecting the best products for your specific industry application, ISK BEARINGS offers application support as part of our value-added services to make your job easier.

Choosing the right bushings involves considering multiple factors, including:

Choosing the right bushings involves considering multiple factors, including:

(1) Pressure:

Select bushings made from appropriate materials and structures based on the operational load of the equipment to ensure they can withstand the expected working pressure.

(2) Speed:

Different bushing materials have varying adaptability to operating speeds; choose the right bushings according to the equipment's operational speed.

(3) PV Value (Pressure-Velocity Product):

Consider the PV value, which is the product of pressure and velocity that the bushing will experience during operation, to ensure durability.

(4) Load Nature:

Choose the appropriate type of bushing based on the nature of the equipment's load (e.g., static or dynamic load).

(5) Lubrication Condition:

The presence and condition of lubrication will also impact the performance and lifespan of the bushings.

Bushings, due to their simple structure, low cost, and durability, are widely used in multiple fields, including but not limited to:

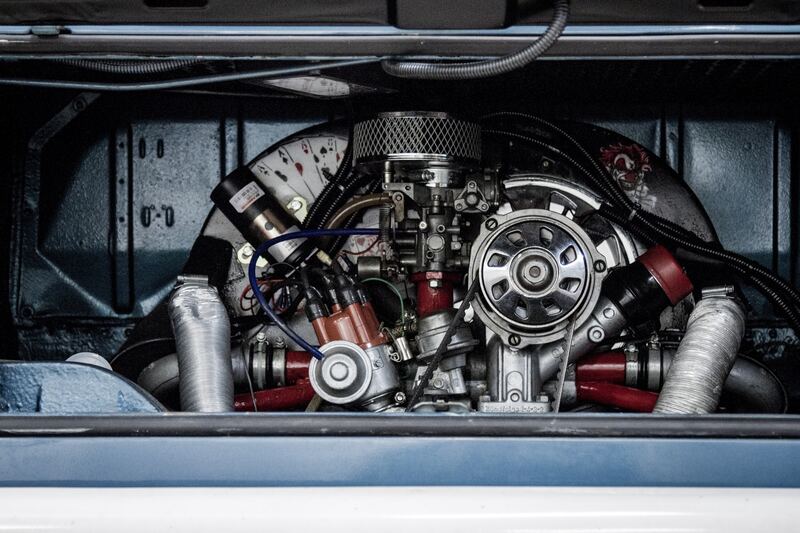

Bushings are used in areas such as engines, gearboxes, and suspension systems to reduce direct metal-to-metal contact, thereby decreasing noise and vibration.

In machine tools, conveyor equipment, and pump systems, bushings are used to support rotating components and ensure smooth operation.

In appliances such as washing machines, refrigerators, and air conditioners, bushings reduce friction during operation, thus extending their lifespan.

In agricultural equipment such as tractors and harvesters, bushings reduce wear on mechanical components, thereby improving operational efficiency.

Bushings are also used in packaging machinery, textile machinery, mining machinery, and other applications. They are known for their ability to handle high torque, high precision, easy installation and removal, simple operation, and excellent positioning. This reduces the scrap rate of shaft and hub fittings, allows for reuse without damaging mating surfaces, and is considered the most ideal and economical choice currently available.

|

Bearing No. |

d(mm) |

D(mm) |

L(mm) |

|---|---|---|---|

DU 0606 DU 0606 |

6 | 8 | 6 |

DU 0608 DU 0608 |

6 | 8 | 8 |

DU 0610 DU 0610 |

6 | 8 | 10 |

DU 0806 DU 0806 |

8 | 10 | 6 |

DU 0808 DU 0808 |

8 | 10 | 8 |

DU 0810 DU 0810 |

8 | 10 | 10 |

DU 0812 DU 0812 |

8 | 10 | 12 |

DU 0815 DU 0815 |

8 | 10 | 15 |

DU 1006 DU 1006 |

10 | 12 | 6 |

DU 1008 DU 1008 |

10 | 12 | 8 |

DU 1010 DU 1010 |

10 | 12 | 10 |

Its main functions include reducing friction, minimizing vibration, corrosion resistance, noise reduction, facilitating maintenance, and simplifying the structure of mechanical equipment.

Materials for bushings include soft metals (such as bronze, steel), rubber, nylon, and various non-metallic polymers.

The replacement frequency of bushings depends on their working environment and usage conditions.

Why is ISK BEARINGS frequently chosen as the specified bearing brand by major international companies?

Need Assistance Selecting The Proper Bushings?

If you need help selecting the best products for your specific industry application, ISK BEARINGS offers application support as part of our value-added services to make your job easier.

Extended Reading: Bearing Bushing Basics: Your Entry Point to Engineering Excellence

Extended Reading: Bearing Bushing Basics: Your Entry Point to Engineering Excellence

Extended Reading: Chrome Steel vs. Stainless Steel Bearings

Extended Reading: Chrome Steel vs. Stainless Steel Bearings

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.