Need Support?

Please provide your question. We’ll find you with the best support options.

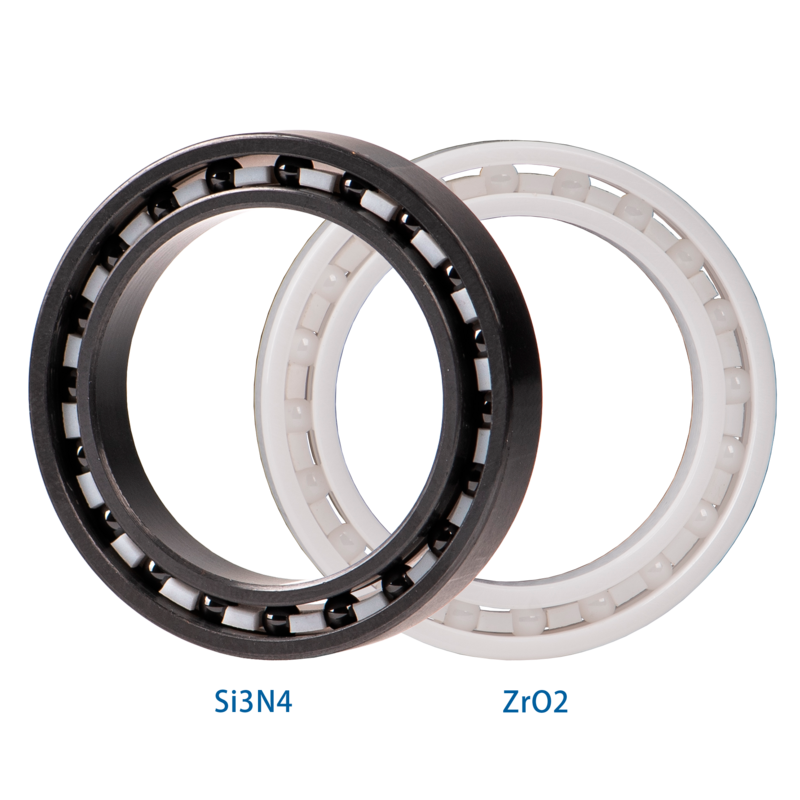

Ceramic bearings are a special type of bearing in which both the rolling elements and the inner and outer rings are made of ceramic materials. Traditional bearings are typically made of metal or alloy materials, while ceramic bearings utilize the properties and advantages of ceramics.

zirconia ceramics (ZrO2) and silicon nitride ceramics (Si3N4). Both of these materials have excellent characteristics, allowing ceramic bearings to perform exceptionally well in specific applications.

Further Reading: Ceramic Bearings: Pioneering High-Performance Technology

Further Reading: Ceramic Bearings: Pioneering High-Performance Technology

The main purpose of thrust bearings is to support or control axial loads, ensuring smooth operation of rotating mechanical components. They are commonly used in applications where axial forces are present, such as automotive transmissions, clutches, fans, pumps, and compressors.

Thrust bearings typically consist of one or more axial balls or rollers housed within a bearing seat. Their design allows them to withstand high axial loads while maintaining low friction. A retainer is often present between the balls or rollers and the shaft to keep them properly positioned.

Thrust bearings are generally classified into two types: unidirectional and bidirectional.

Unidirectional bearings can only withstand forces in one direction, while bidirectional bearings can handle forces in both directions. The selection of the appropriate thrust bearing depends on the required load capacity and specific requirements of the application.

In summary, thrust bearings are designed to handle axial loads and provide stable operation with low friction. They play a critical role in many mechanical applications, ensuring the reliable operation of rotating equipment.

Further Reading: What are thrust bearings, are there different types of thrust bearings

Further Reading: What are thrust bearings, are there different types of thrust bearings

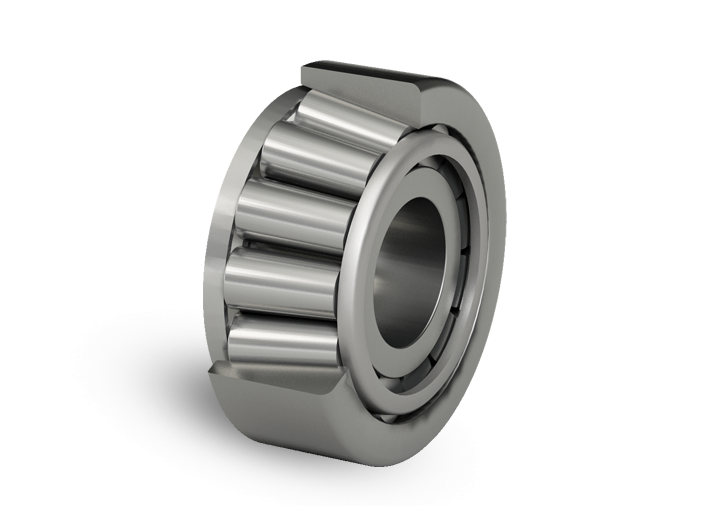

The contact angle between the inner and outer rings can be adjusted to accommodate different load conditions. Generally, the larger the contact angle of the tapered roller bearings, the higher the axial load-carrying capacity.

Additionally, tapered roller bearings have good radial load-carrying capacity. Due to the unique shape of their rolling elements, they can achieve relatively higher stiffness and stability in both radial and axial directions.

Tapered roller bearings find wide applications in various industries such as automotive, machinery, aerospace, etc., particularly in applications that require smooth operation under significant axial and radial loads.

Tapered roller bearings are extensively used in various industrial machinery, especially in automotive, aerospace, shipbuilding, railway, and construction fields. Common applications include automotive wheel bearings, transmission systems, construction machinery, and train vehicles.

Further Reading: What is a Tapered Roller Bearing, this article provides a detailed introduction to tapered roller bearings.

Further Reading: What is a Tapered Roller Bearing, this article provides a detailed introduction to tapered roller bearings.

Please provide your question. We’ll find you with the best support options.