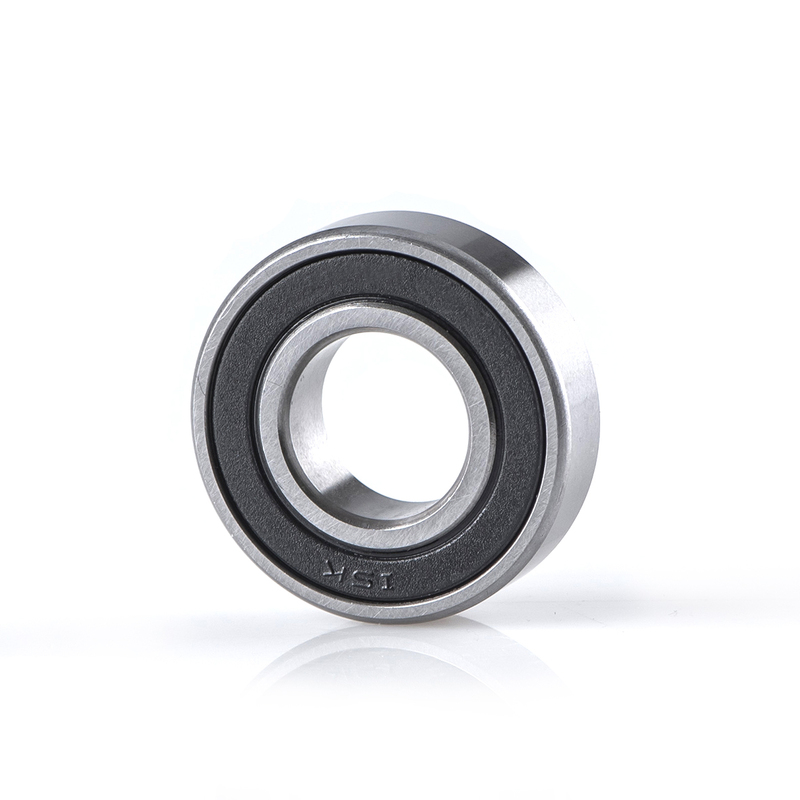

Sealed ball bearings, as the name suggests, are designed with an integrated sealing mechanism that encases the bearing in a protective barrier. This seal is typically made of rubber, metal, or a combination of materials, and it serves several important functions:

Sealed ball bearings, as the name suggests, are designed with an integrated sealing mechanism that encases the bearing in a protective barrier. This seal is typically made of rubber, metal, or a combination of materials, and it serves several important functions:

(1) Contaminant Protection:

Sealed ball bearings create a barrier that prevents dust, dirt, moisture, and other contaminants from entering the bearing. This protection is especially crucial in industries where cleanliness is paramount, such as the food and pharmaceutical sectors.

(2) Lubrication Retention:

The sealing mechanism helps retain lubricants within the bearing, ensuring consistent lubrication over time. This results in reduced friction, less heat generation, and extended bearing life.

(3) Reduced Maintenance:

Sealed ball bearings are known for their low maintenance requirements. By preventing contaminants from entering and retaining lubrication, they reduce the need for frequent re-greasing and servicing.

(4) Corrosion Resistance:

The seals also provide a degree of corrosion resistance, making sealed ball bearings suitable for applications exposed to harsh environments, such as outdoor settings.

3. Advantages of Sealed Ball Bearings

Sealed ball bearings are built to last. The protective seal helps prevent wear and damage to the bearing's internal components, resulting in a longer operational life.

(1) Longevity:

Sealed ball bearings are built to last. The protective seal helps prevent wear and damage to the bearing's internal components, resulting in a longer operational life.

(2) Reduced Friction:

The sealed design minimizes friction and heat generation, contributing to smoother operation and increased energy efficiency.

(3) Lower Maintenance Costs:

With less frequent maintenance requirements, sealed ball bearings reduce downtime and maintenance expenses, making them a cost-effective choice in the long run.

(4) Versatility:

Sealed ball bearings come in various sizes, load capacities, and configurations, making them suitable for a wide range of applications, from automotive wheels and electric motors to conveyor systems and agricultural machinery.

(5) Contamination Prevention:

In applications where cleanliness is essential, such as medical devices or semiconductor manufacturing equipment, sealed ball bearings are the preferred choice for keeping contaminants at bay.

4. What is Better Sealed or Shielded Bearings?

.jpg)

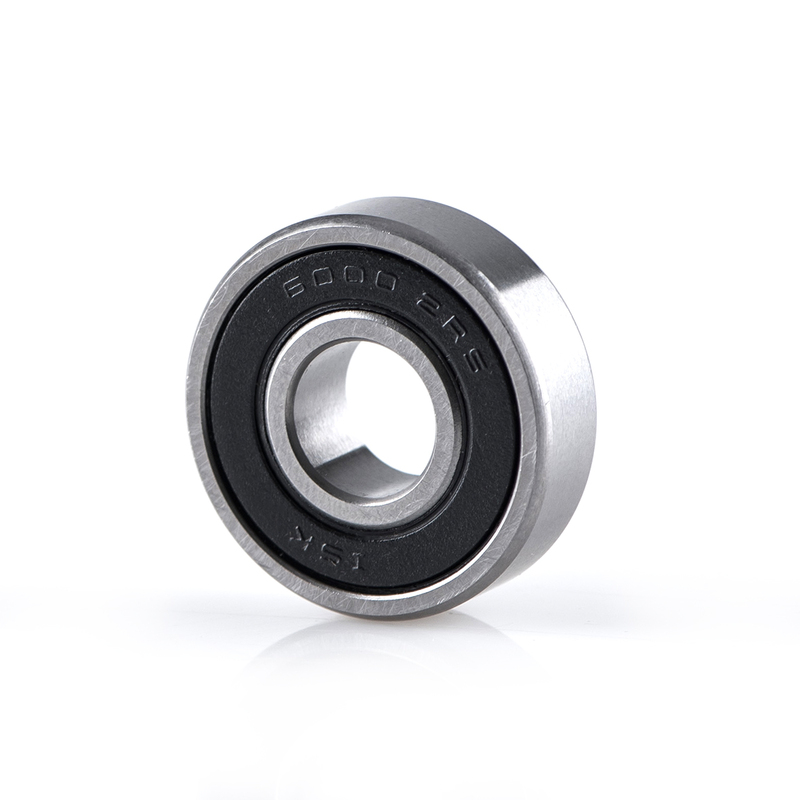

(1) Sealed Bearings

Sealed bearings feature an internal closure structure that effectively prevents external contaminants from entering the bearing. This design helps extend the bearing's lifespan, reduce maintenance requirements, and enhance operational efficiency. The sealing structure of sealed bearings is typically made of rubber or metal, effectively blocking dust, moisture, and other elements that could potentially damage the bearing.

Application scenarios of sealed bearings

Sealed bearings are particularly suitable for environments with harsh conditions, such as dusty, humid, or high-temperature surroundings. The sealing structure provides higher protective performance, ensuring stable operation even in challenging conditions.

1688%E4%B8%BB.jpg)

(2) Shielded Bearings

Shielded bearings, also known as metal-shielded bearings, have a relatively simpler structure, usually with metal shields covering the outer ring of the bearing. This design is more straightforward compared to sealed bearings, making it more economically practical in some applications.

Application Scenario

Shielded bearings are suitable for relatively clean environments where there is less intrusion of dust or moisture. They are commonly found in lightweight mechanical applications where reduced weight and friction are crucial.

The choice between sealed and shielded bearings should be based on the specific requirements of the application. If the operating environment is harsh, and high protection is needed, sealed bearings may be the preferred choice. However, in cleaner environments where cost and reduced friction are considerations, shielded bearings may be more suitable. Understanding the advantages and application scenarios of both types of bearings helps ensure a wise and cost-effective choice in specific engineering projects.

5. Applications of Sealed Ball Bearings

Sealed ball bearings find applications across numerous industries, including:

Sealed ball bearings find applications across numerous industries, including:

(1) Automotive

Sealed ball bearings are commonly used in wheel hubs, transmission systems, and electric power steering units to ensure smooth and reliable vehicle performance.

(2) Industrial Machinery

From conveyor belts and pumps to electric motors and gearboxes, sealed ball bearings play a vital role in industrial equipment, where durability and reliability are crucial.

(3) Household Appliances

Refrigerators, washing machines, and blenders rely on sealed ball bearings for smooth operation and longevity.

(4) Agriculture

Tractors, combines, and other farming equipment benefit from sealed ball bearings that withstand the rigors of the field.

Sealed ball bearings are an indispensable component in various industries, offering longevity, reduced maintenance costs, and enhanced performance. Their ability to protect against contaminants, retain lubrication, and resist corrosion makes them a top choice for applications where reliability is paramount. Whether in the automotive, industrial, or household sector, sealed ball bearings continue to play a pivotal role in ensuring efficient and trouble-free machinery operation. Consider using them in your next project to experience the many benefits they offer.

Further reading:

Further reading:

Contact Us

Contact Us

TOP

TOP