Need Support?

Please provide your question. We’ll find you with the best support options.

Table of content

1. Using high-performance materials

2. Rigorous salt spray testing

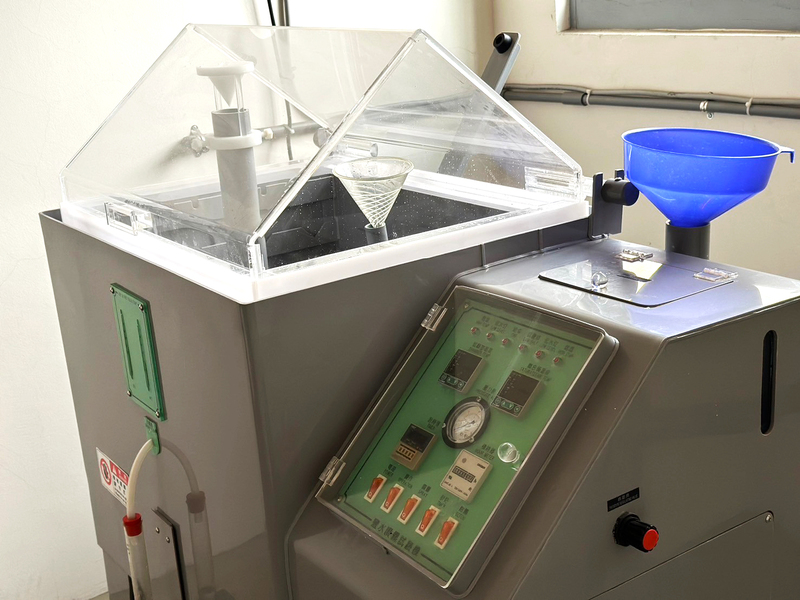

In modern industrial applications, the durability and stability of stainless steel bearings are crucial. To ensure our stainless steel bearings maintain excellent performance in various harsh environments, we employ rigorous salt spray testing to assess their corrosion resistance.

%E4%B8%BB1688.jpg)

.jpg)

Our stainless steel bearings are made from high-performance materials such as SUS440C, SUS304, and SUS316. These materials are renowned for their excellent resistance to acids, alkalis, corrosion, and high temperatures, ensuring stable performance even under extreme conditions.

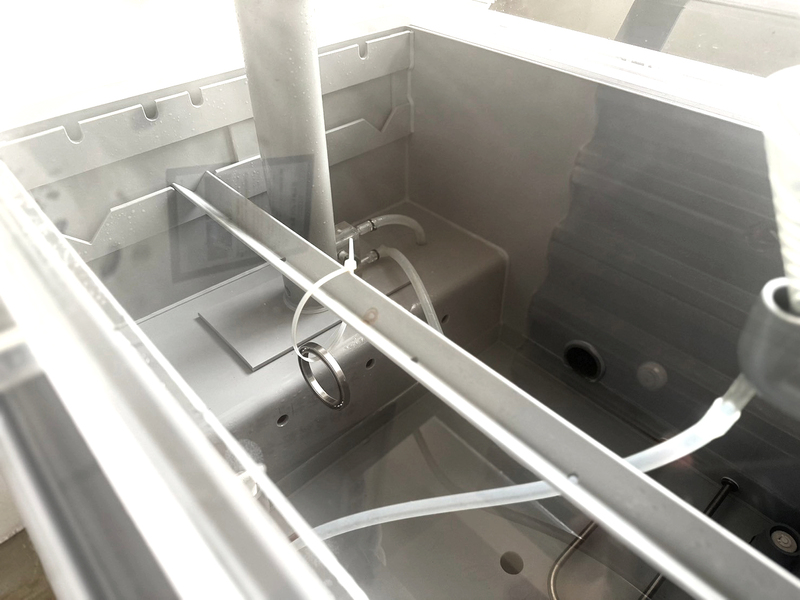

Salt spray testing is a method used to simulate corrosive environments, evaluating the durability and stability of stainless steel bearings. We use salt spray testing to ensure these materials can perform well in corrosive mediums. Specific test environments include:

With our stainless steel bearings tested under salt spray conditions, your equipment will operate for longer durations in the most severe environments, significantly reducing maintenance frequency and costs. This not only enhances overall operational efficiency but also ensures excellent performance under high-pressure and low-load conditions.

Our stainless steel bearings undergo rigorous salt spray testing to ensure they perform exceptionally well in corrosive environments. This means that under high-pressure and high-load operating conditions, your equipment can maintain stable operation, thereby improving production efficiency and reducing operating costs.

By choosing our stainless steel bearings, you will have a reliable and durable solution, ensuring your equipment operates efficiently even in the most demanding environments. Let's work together to enhance equipment efficiency and achieve optimal performance across various industrial applications.

If you're unsure about which bearing to choose, it's advisable to consult with a professional engineer or bearing supplier to ensure your equipment achieves optimal performance and longevity.

Three Assurances

Three Assurances"Quality, integrity, and service" are the three guarantees of ISK.

Need Assistance Selecting The Proper Bearings?

If you need help selecting the best products for your specific industry application, ISK BEARINGS offers application support as part of our value-added services to make your job easier.

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.