Need Support?

Please provide your question. We’ll find you with the best support options.

Unsure? Contact us for free advice

Table of content

1. Introduction about bearing sleeve types

2. Bearing sleeve types - DU PTFE composite bushing (Oilless bearing)

3. Bearing sleeve types - DX POM composite bushing

4. Bearing sleeve types - Bimetal bushing

This guide focuses on six common bearing sleeve types used in many industrial applications: DU PTFE composite bushings, DX POM composite bushings, bimetal bushings, bronze wrapped bearings, and solid lubricant inlaid bearings. The goal is to help you quickly understand their structure, features, and typical uses so you can choose a suitable bushing for your project.

When choosing bearing sleeve types, you should consider whether you need an opening, how big it should be, and how tall you are, rather than clearance and tolerance. Generally, you need an opening (there is no standard for openings you can ask for a free torch).

Compared with other bearing sleeve types , it does not need oil at all, it relies on lubrication to rotate smoothly.

Compared with other bearing sleeve types , it does not need oil at all, it relies on lubrication to rotate smoothly.

Oilless Slide Bushing is made of the PTFE composite material, which is a copper-plated steel plate on which a porous layer of tin bronze powder is sintered and a mixture of PTFE and lead is filled into and covered by a porous layer by a rolling process.

It is a boundary lubricating bushes made of the POM composite material, which also has a copper-plated steel plate on which a tin bronze powder is sintered, and modified polyformaldehyde resin (POM) is firmly anchored in the sintered bronze layer. The surface of the covering layer has many pockets to retain lubricating grease.

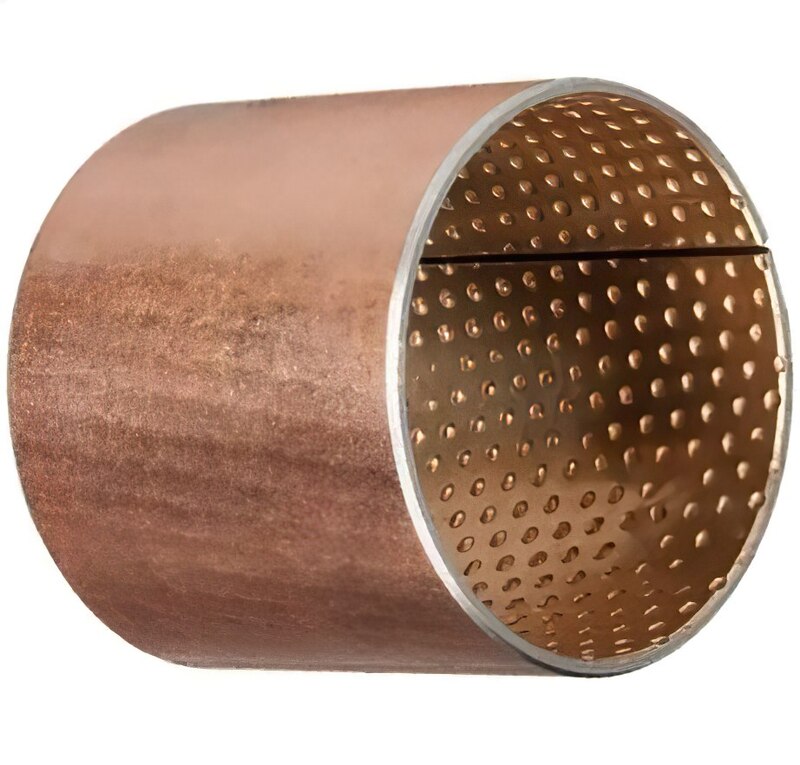

Based on high-quality low carbon steel sintering bronze alloy or lead-free bronze alloy on the surface, provide a high specific load, especially fits for high speed and shock conditions.

Oil pockets or grooves can be machined in the liner for better grease storage. Widely used in truck chassis, agricultural machinery, construction machinery, etc. In addition, lead-free meet EU requirements and are the a popular option for many automotive applications.

%20(1).jpg)

The bearing sleeve types is wrapped in a cold form of able homogenous bronze, which will obtain favorable material properties for bearing applications.. Standard bearings are equipped with diamond-shaped lubrication grooves on the bearing surface. These indentations act as lubricant reservoirs and rapidly form a lubricating film during the start-up motion, reducing start-up friction. Typical applications are widely used in construction machinery such as hoisting machinery, automobiles, tractors, trucks, machine tools, and some mining engines.

This type of bearings material provides a maintenance-free and low-friction bearing especially suitable for high loads and intermittent oscillating motion. Solid lubricants in bronze combine the strength of bronze with the wear resistance of graphite. Applications are used in automotive production lines, water industry, dam gates, plastic molding machinery, etc.

| DU PTFE | DX POM | |

| 1 | PTFE and lead | POM |

| 2 | Tin Bronze Powder | Tin Bronze Powder |

| 3 | Copper Layer | Copper Layer |

| 4 | Steel Backing | Steel Backing |

| 5 | Copper Layer | Copper Layer |

| Compressive strength (Mpa) | Temperature range (℃) | Coefficient of friction | Width of wear (mm) | PV factor limit (Mpa. m/s) | Wear depth limit (mm) | Thermal conductivity Kcal/M.br.C | Coefficient of linear expansion(per C) | |

| DU PTFE | 280 | -195~+270 | <0.20 | <0.55 | 3.6 | 0.05 | 2.41 | 27*10^5 |

| DX POM | 140 | -20~+100 | <0.20 (grease) | <4.5 (grease) | 10 (grease) | 0.50 | 2.03 | 5.1*10^-5 |

| Bearing sleeve type | Lubrication style | Typical features / uses |

|---|---|---|

| DU PTFE composite bushing | Dry running or with very little grease | Good for applications that need low friction and maintenance-friendly operation. |

| DX POM composite bushing | Boundary lubrication with grease | Suitable for high load & low speed with frequent start/stop movements. |

| Bimetal bushing | Grease or oil lubrication | Used in vehicle chassis, agricultural and construction machinery. |

| Bronze wrapped bearing | Grease lubrication stored in grooves | Common in construction, lifting, and general machinery. |

| Solid lubricant inlaid bearings | Self-lubricating solid lubricant | Used where re-lubrication is difficult, with intermittent or oscillating motion. |

Discover more about the features and applications of various bearings.

Click here to explore more articles and find the perfect bearing for your project.

Needle Bearings (Roller Bearings) are a type of bearing that performs exceptionally well at high speeds. Their rollers are precisely guided by specially shaped, high-rigidity cages with minimal dimensional error. Despite their small cross-section, needle bearings...

How Do Ball Bearings Work? Bearings are often small and unassuming components in a product, yet they are crucial for its proper functioning. Without bearings, many products would fail to operate effectively. But do you know how ball bearings...

Please provide your question. We’ll find you with the best support options.