Need Support?

Please provide your question. We’ll find you with the best support options.

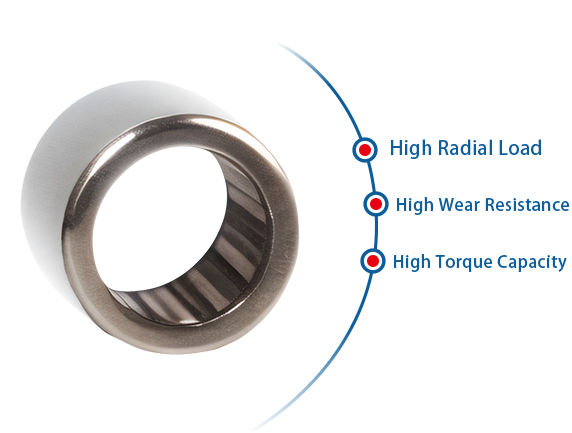

Needle roller bearings, commonly known as needle bearings, are a specialized type of rolling bearing distinguished by their slender and elongated needle-shaped rollers. These bearings are highly regarded for their precision and compact design, making them ideal for applications with limited space, especially when facing radial space constraints.

Compared to traditional ball bearings, needle roller bearings have a smaller cross-sectional area and volume, yet they boast a higher load-carrying capacity. This unique characteristic allows needle bearings to excel in various industries where space optimization and load-bearing capacity are paramount.

One of the key advantages of needle roller bearings is their ability to withstand high loads despite their smaller outer diameter and volume. This quality is particularly advantageous for applications that require miniaturization, lightweighting, and precision engineering in machinery. Additionally, the reduced rotating radius of needle roller bearings results in lower rotational torque under the same friction force, enhancing mechanical efficiency significantly.

As a reputable Taiwan bearing supplier, we take pride in offering a diverse range of needle roller bearings to cater to a wide array of demands. Our product lineup includes stamped outer ring needle roller bearings, one-way clutch needle roller bearings, solid ring needle roller bearings, thrust needle roller bearings, cage assembly bearings, bolt-type roller bearings, and linear bearings, among others. This extensive variety allows needle roller bearings to find extensive applications in industries such as automotive, motorcycles, printing machinery, industrial robots, and construction equipment.

At our company, we are committed to delivering high-quality needle bearings that meet our customers' specific requirements. Whether you need bearings for automotive applications, printing machinery, or industrial robots, our comprehensive range ensures that you find the perfect solution for your needs. Trust us as your reliable partner for top-notch needle roller bearings that guarantee superior performance and durability.

Please provide your question. We’ll find you with the best support options.