Need Support?

Please provide your question. We’ll find you with the best support options.

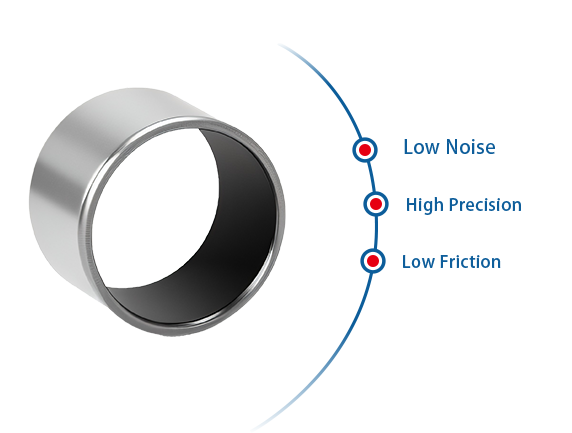

The basic structure of the self-lubricating bearing is manufactured by sintering three-layer composite materials, and the outermost layer is made of SPCC elastic steel plated, capable of withstanding an applied force of 300kgf per square centimeter.

The bearing manufacture process continues with the middle layer, a lead bronze sintered layer, responsible for roughening the surface of the SPCC steel and enhancing the strength of PTFE+ additives. The copper layer's heat transfer characteristics enable efficient transmission of heat to the machine wall through the outer layer.

The innermost layer is PTFE (Teflon), which is manufactured to reduce the friction coefficient and minimize the amount of friction.

Bush bearings can reduce the frequency of oil supply or the amount of oil, or they can be used as bearings without oil supply, manufactured for situations where oiling and maintenance are challenging. They are intended to reduce maintenance intervals, decrease the overall volume, and save space.

Thanks to the bearing manufacture expertise, these oil-impregnated self-lubricating bearings are specifically designed to prevent burning and reduce wear, ensuring prolonged and efficient usage.

Further Reading: What is a Bushing?

Further Reading: What is a Bushing?

Please provide your question. We’ll find you with the best support options.